原著論文(レフェリー審査あり)

166報

論文リスト

2019年

1報

| 2019- 1. | Tsukasa Sugawara, Isao Hirano, Kensuke Kobayashi, Akira Kawai "Application of Polyimide Porous Membrane to Photopolymer Filter" J. Photopolymer Science and Technology, 32(6), 791-794 (2019) |

2018年

2報

| 2018- 1. | Tsukasa Sugawara, Jun Koshiyama, and Akira Kawai "Novel Fabrication of Three-Dimensional Homogeneous Microporous Polyimide Membrane" J. Photopolymer Science and Technology, 31(3), 437-440 (2018) |

| 2018- 2. | Tsukasa Sugawara, Hiroyoshi Sago, and Akira Kawai "In-Situ Observation of Permeation Behavior and Structural Analysis of Polyimide Membrane with Electrical Properties" J. Photopolymer Science and Technology, 31(6), 735-738 (2018) |

2017年

2報

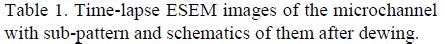

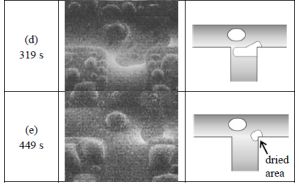

| 2017- 1. | Natsumi Yagi and Akira Kawai "Three-Dimensional Analysis of Liquid Propagation at Microchannel Junction using ESEM" J. Photopolymer Science and Technology, 30(6), 709-714 (2017)[abstract] |

| 2017- 2. | Katsuaki Yamane and Akira Kawai "Application to Artificial Skin of Double Cone Tube Made of Acrylic Resin Formed by Micro Stereolithography" J. Photopolymer Science and Technology, 30(3), 345-350 (2017) [abstract] |

2016年

3報

| 2016- 1. | Hiroki Nakano, Kenta Takahashi, Akira Kawai "Negative pattern formation in positive resist layer by EB / UV hybrid lithography" J. Photopolymer Science and Technology, 29(4), 603-606 (2016) in perss. [abstract] |

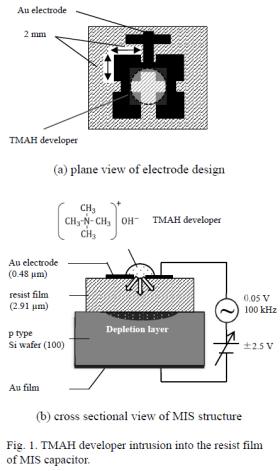

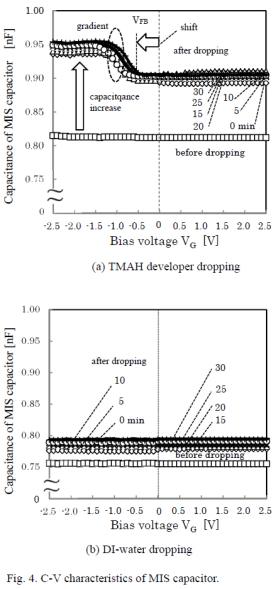

| 2016- 2. | Hodaka Shirataki, Akira Kawai "In-situ Monitoring of TMAH Developer Intrusion into Resist Film by C-V Method" J. Photopolymer Science and Technology, 29(6), 817-822 (2016) [abstract] |

| 2016- 3. | Natsumi Yagi, Akira Kawai "Effect of Sub-Pattern on Guiding Liquid Propagation at Microchannel Junction" J. Photopolymer Science and Technology, 29(6), 833-834 (2016) [abstract] |

2014年

2報

| 2014- 1. | Yako Kunii, Akira Kawai "Tactile senses control by contacting a human finger with micro resist pattern arrangements" J. Photopolym. Sci. Technol., 27 (6) 691-694(2014) (IF: 1.055) [abstract] |

| 2014- 2. | Akira Kawai, Shogo Ohtani "Frequencydispersion of permittivity of SU-8 resist thin film" J. Photopolym. Sci. Technol., 27 (6) 711-712 (2014) (IF: 1.055) [abstract] |

2013年

7報

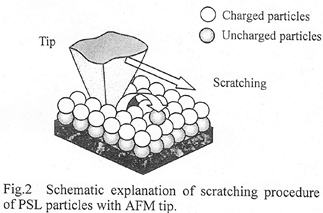

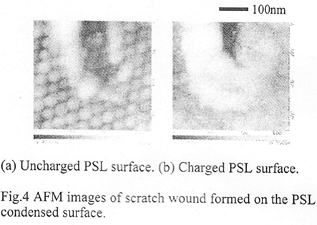

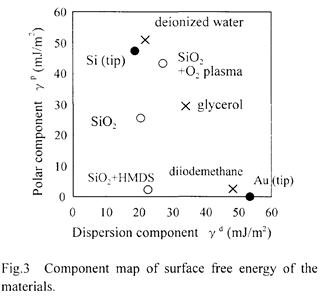

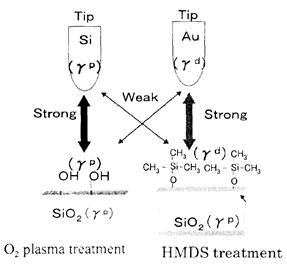

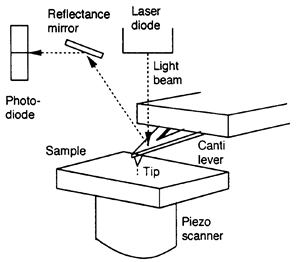

| 2013- 1. | Akira Kawai “Electrification on Condensation Surface of Micro Particles with Atomic Force Microscope (AFM)” J. Photopolymer Science and Technology, 26(6), 705-706 (2013). (IF: 0.908) [abstract] |

| 2013- 2. | Yuta Noguchi, Akira Kawai “Local Heating System Integrated with Platinum Micro Heater and Photopolymer Microfluidic Channel” J. Photopolymer Science and Technology, 26(6), 713-716 (2013). (IF: 0.908) [abstract] |

| 2013- 3. | Kazutoshi Otsuka, Kenta Takahashi, Akira Kawai “Fabrication of Micro Tube Array by Combining Positive with Negative Type Photoresists due to Solubility Difference in Developer” J. Photopolymer Science and Technology, 26(6), 717-720 (2013). (IF: 0.908) [abstract] |

| 2013- 4. | Yosuke Sakurai, Kenta Takahashi, Akira Kawai “Liquid Penetration Control of Photoresist/Perfluorosulfonic Acid (PFSA) Double Layer Structure by Hydrophobic Treatment” J. Photopolymer Science and Technology, 26(6), 727-732 (2013). (IF: 0.908) [abstract] |

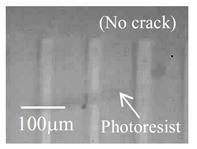

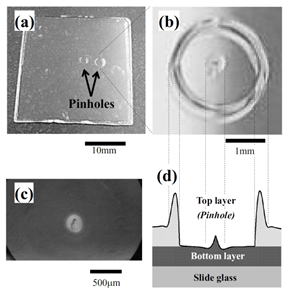

| 2013- 5. | Yuta Noguchi, Kenta Takahashi, Akira Kawai “Micro Pinhole Formation in Photoresist Multilayer Structure controlled with Hydrophilic Treatment” J. Photopolymer Science and Technology, 26(6), 739-744 (2013). (IF: 0.908) [abstract] |

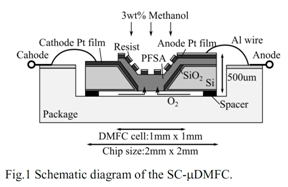

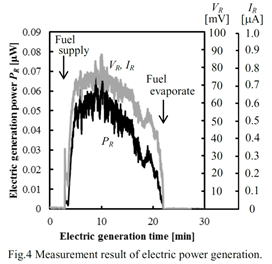

| 2013- 6. | Yosuke Sakurai, Daisuke Tanaka, Shunsuke Ohata, Akira Kawai “Fabrication and Durability of Single Chip Micro Direct Methanol Fuel Cell (SC-μDMFC) by Photolithography Process” J. Photopolymer Science and Technology, 26(6), 751-756 (2013). (IF: 0.908) [abstract] |

| 2013- 7. | Kenta Takahashi, Akira Kawai “Effect of Low Surface Tension Developer on Micro Bubble Removal from Resist Square Window Pattern” J. Photopolymer Science and Technology, 26(6), 765-768 (2013). (IF: 0.908) [abstract] |

2012年

4報

| 2012- 1. | Yuta Noguchi, Akira Kawai “Surface Stability of SU-8 film for Accurate Biopotential Detection” J. Photopolymer Science and Technology, 25(6), 719-722 (2012). (IF: 0.984) [abstract] |

| 2012- 2. | Yosuke Sakurai, Akira Kawai “Mechanical Stress Effect on Ionic Conductivity of Perfluorosulfonic Acid (PFSA) Film by Photolithography” J. Photopolymer Science and Technology, 25(6), 723-727 (2012). (IF: 0.984) [abstract] |

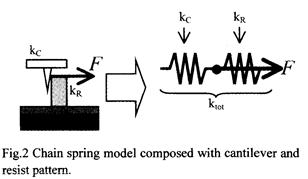

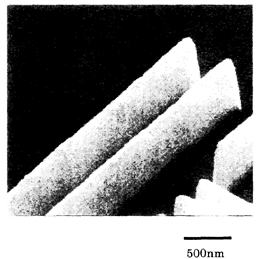

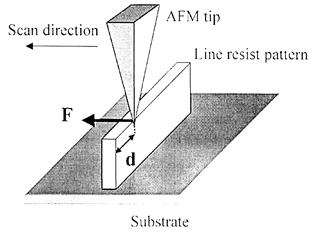

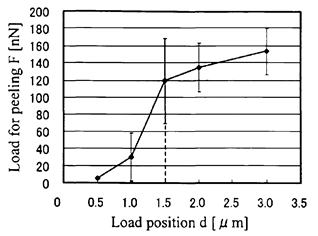

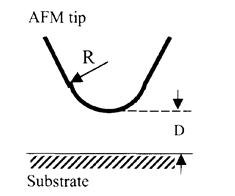

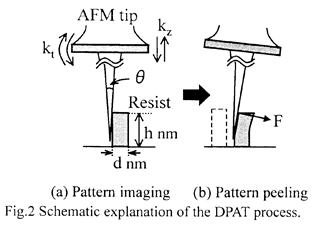

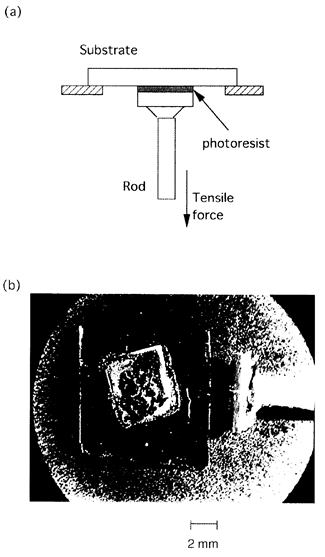

| 2012- 3. | Takashi Aiba, Akira Kawai “Micro Cantilever Motion in Micro Pattern Peeling by DPAT Method” J. Photopolymer Science and Technology, 25(6), 729-733 (2012). (IF: 0.984) [abstract] |

| 2012- 4. | Satoru Mori, Akira Kawai “Interfacial Microstructure of a Double-layer Cu Film Consisting of an Under-layer Deposited on SiO2 Substrate in Ar-10 vol% O2 and an Upper-layer Deposited in Pure Ar” J. Adhesion Soc. Japan, 48(1), 10-16 (2012). [abstract] |

2011年

2報

| 2011- 1. | Akira Kawai “Fluid Control MEMS constructed with Polymer Materials” J. Photopolymer Science and Technology, 24(5), 587-593 (2011). (IF: 0.904) [abstract] |

| 2011- 2. | Masayoshi Yamada, Akira Kawai “Micro Polymer Capsule Constructed with Micro Pillars Formed by Multi Laminating Method” J. Photopolymer Science and Technology, 24(6), 647-650 (2011). (IF: 0.904) [abstract] |

2010年

6報

| 2010- 1. | Satoru Mori, Akira Kawai “Low-Resistivity and Adhesive Sputter-Deposited Cu-Ca Films with an Intermediate Oxide Layer” Jpn. J. Appl. Phys., 49 (2010) p075804-1~8. (IF: 1.024) [abstract] |

| 2010- 2. | Tetsuya Ono, Akira Kawai “Free fall Mechanism of Micro Liquid Droplet” J. Photopolymer Science and Technology, 23(3), 363-366 (2010). (IF: 1.029) [abstract] |

| 2010- 3. | Masayoshi Yamada, Akira Kawai “Characterization of Resist Micro Pattern Adhesion by Applying Ultrasonic Vibration” J. Photopolymer Science and Technology, 23(3), 435-438 (2010). (IF: 1.029) [abstract] |

| 2010- 4. | Shunsuke Ohata, Akira Kawai “Dielectric Property of Solution Analyzed by using pn-junction Array” J. Photopolymer Science and Technology, 23(3), 367-370 (2010). (IF: 1.029) [abstract] |

| 2010- 5. | Junji Miyazaki, Nobuhito Toyama, Akira Kawai “Double Patterning Analysis Method by Emulation using a Double-Exposure Technique” Jpn. J. Appl. Phys., 49 (2010) p035201-1~6. (IF: 1.024) [abstract] |

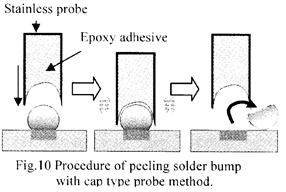

| 2010- 6. | 山田昌佳、河合 晃、大澤義征、宝泉俊寛 「超音波プローブ振動法によるはんだバンプの付着性解析」 Microjoining and Assembly Technology in Electronics (Mate), 93-98 (2010) [abstract] |

2009年

5報

| 2009- 1. | Junji Miyazaki, Akira Kawai “Fidelity of Mask Shape and Use of a Correction Method in Anisotropic Si Wet Etching” J. Photopolymer Science and Technology, 22(6), 731-735 (2009). (IF: 0.780) [abstract] |

| 2009- 2. | Akihiro Takano, Akira Kawai “Analysis of self-standing structure composed by thick resist layer” J. Photopolymer Science and Technology, 22(5), 561-564 (2009). (IF: 0.780) [abstract] |

| 2009- 3. | Hiroki Sasazaki, Akira Kawai “Dielectric dispersion analysis of resist layer” J. Photopolymer Science and Technology, 22(3), 317-320 (2009). (IF: 0.780) [abstract] |

| 2009- 4. | Junji Miyazaki, Akira Kawai “Formation Mechanism of Micro Defect in Anisotropic Etching Analyzed by using Quasi-defect Pattern” J. Photopolymer Science and Technology, 22(3), 313-316 (2009). (IF: 0.780) [abstract] |

| 2009- 5. | Junji Miyazaki, Akira Kawai “Characterization of photomask substrate in optical lithography” J. Photopolymer Science and Technology, 22(5), 555-559 (2009). (IF: 0.780) [abstract] |

2008年

11報

| 2008- 1. | Daisuke Tanaka, Akira Kawai “Flowing control of micro bubbles in DFR micro fluidic channel formed on metal /insulator composite substrate” J. Photopolymer Science and Technology, 21(1), 63-68 (2008). (IF: 1.140) [abstract] |

| 2008- 2. | Akira Kawai, Daisuke Tanaka, Sachito Matsubara, Masayoshi Ogata, Kazutoshi Tachibana “Wetting control of polymer solution on roughened solid surfaces by wet-blast technique” J. Photopolymer Science and Technology, 21(1), 37-42 (2008). (IF: 1.140) [abstract] |

| 2008- 3. | Akira Kawai, Daisuke Tanaka, Tomotaka Ariga “Micro channel device composed by Dry film resist” J. Photopolymer Science and Technology, 21(1), 43-46 (2008). (IF: 1.140) [abstract] |

| 2008- 4. | Akira Kawai, Takashi Yamaji, Hiroshi Horiguchi “Adsorption of micro tip on various surface energy substrates” J. Photopolymer Science and Technology, 21(1), 85-88 (2008). (IF: 1.140) [abstract] |

| 2008- 5. | Takashi Yamaji, Akira Kawai “Non-contact deformation of resist micro pattern due to van der Waals Interaction” J. Photopolymer Science and Technology, 21(1), 89-94 (2008). (IF: 1.140) [abstract] |

| 2008- 6. | Akira Kawai, Masahito Hirano and Takashi Yamaji “Nano-scale Deformation of Resist Film Surface by Humidifying and Drying Processes” J. Photopolymer Sci. Technol., 21(6), 737-738 (2008). (IF: 1.140) [abstract] |

| 2008- 7. | Akira Kawai, Daisuke Tanaka “Micro Bubble Removal Depending on Glass Cleanness” J. Photopolymer Sci. Technol., 21(6), 727-728 (2008). (IF: 1.140) [abstract] |

| 2008- 8. | Akira Kawai, Takashi Yamaji “Internal Stress of Dry Film Resist in Multilayer Structure” J. Photopolymer Sci. Technol., 21(6), 725-726 (2008). (IF: 1.140) [abstract] |

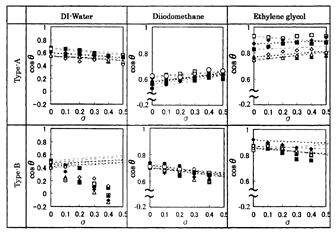

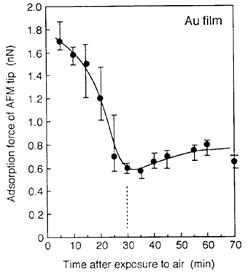

| 2008- 9. | Akira Kawai, Junko Kawakami, Hiroki Sasazaki “Surface Energy change of Si(100) Wafer by Exposing to Air” J. Photopolymer Sci. Technol., 21(6), 739-740 (2008). (IF: 1.140) [abstract] |

| 2008-10. | Akira Kawai, Hotaka Endo and Daisuke Tanaka “Pinning Effect of Micro Bubbles adhered on Resist Substrate” J. Photopolymer Sci. Technol., 21(6), 753-754 (2008). (IF: 1.140) [abstract] |

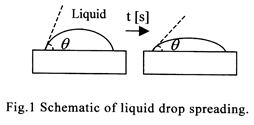

| 2008-11. | Akira Kawai, Akihiro Takano “Spreading of Liquid Drop on Resist Film Surface” J. Photopolymer Sci. Technol., 21(6), 759-760 (2008). (IF: 1.140) [abstract] |

2007年

12報

| 2007- 1. | 河合 晃、川上喜章 「原子間力顕微鏡(AFM)による微細レジストパターン内の屈折率分布の解析」 日本接着学会誌、vol.43, No.4, 140-143 (2007). [abstract] |

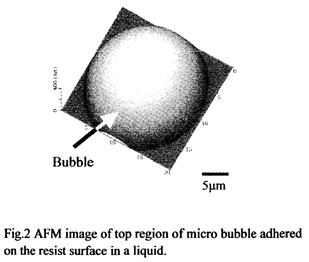

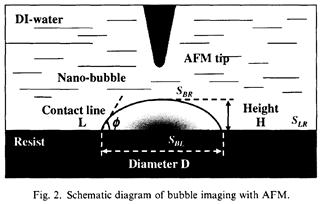

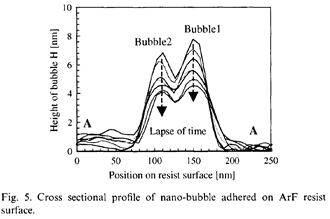

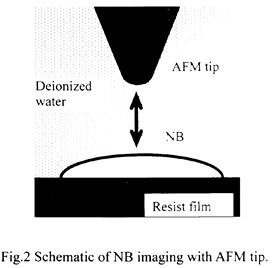

| 2007- 2. | Akira Kawai, Kenta Suzuki “Bubbles Condensed at Water/resist Interface Analyzed by AFM” J. Photopolymer Science and Technology, 20(5), 673-678 (2007). (IF: 0.835) [abstract] |

| 2007- 3. | Akira Kawai, Norio Moriike “Visualization of stress distribution in resist film by surface plasma treatment” J. Photopolymer Science and Technology, 20(6), 783-784 (2007). (IF: 0.835) [abstract] |

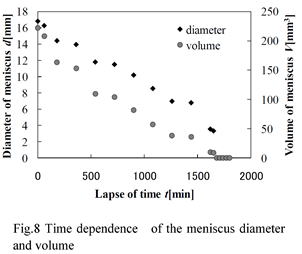

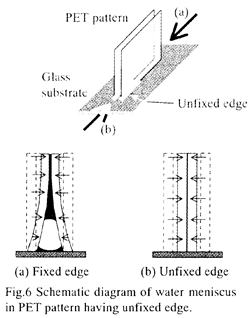

| 2007- 4. | Masaki Yamanaka, Akira Kawai “Analysis of micro meniscus shape by light scattering” J. Photopolymer Science and Technology, 20(6), 781-782 (2007). (IF: 0.835) [abstract] |

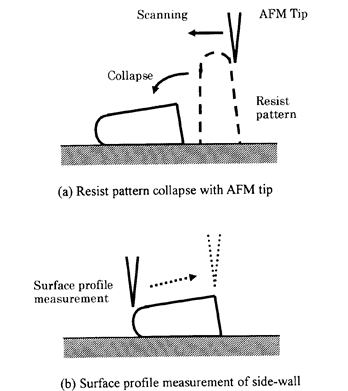

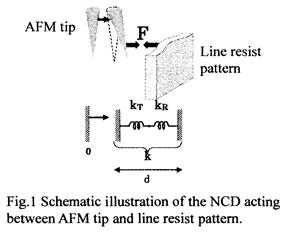

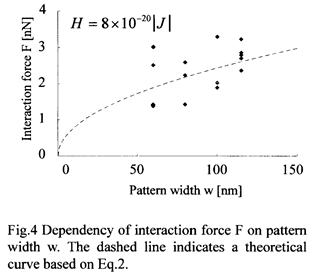

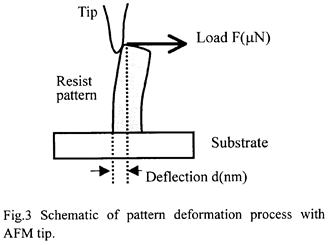

| 2007- 5. | Akira Kawai, Takahiro Moriuchi “Non-contacting deformation (NCD) of line resist pattern due to interaction force with AFM tip” J. Photopolymer Science and Technology, 20(6), 777-780 (2007). (IF: 0.835) [abstract] |

| 2007- 6. | Kenta Suzuki, Akira Kawai “Micro bubbles formed on ArF excimer resist surface detected by tip scanning method” J. Photopolymer Science and Technology, 20(6), 805-806 (2007). (IF: 0.835) [abstract] |

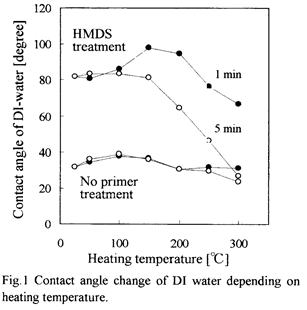

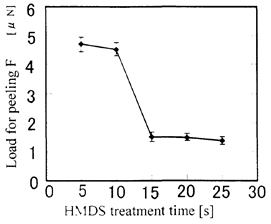

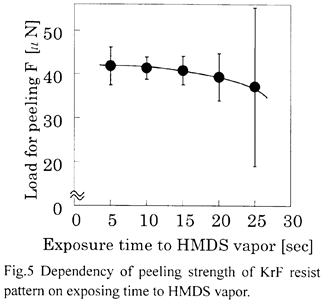

| 2007- 7. | Akira Kawai, Junko Kawakami “Wetting analysis of hydrophobic substrate treated by HMDS primer” J. Photopolymer Science and Technology, 20(6), 815-816 (2007). (IF: 0.835) [abstract] |

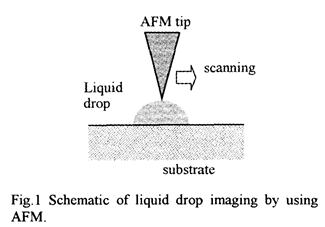

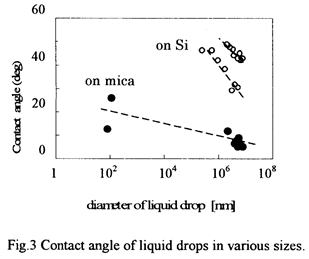

| 2007- 8. | Akira Kawai, Masahito Hirano “Nano-wetting of DI-water analyzed by AFM” J. Photopolymer Science and Technology, 20(6), 813-814 (2007). (IF: 0.835) [abstract] |

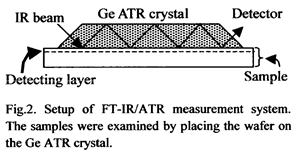

| 2007- 9. | Shingo Kuroda, Tomohiro Goto, Osamu Tamada, Masakazu Sanada, Akira Kawai “Analysis of interface condition between BARC and resist film by FT-IR/ATR” J. Photopolymer Science and Technology, 20(6), 807-808 (2007). (IF: 0.835) [abstract] |

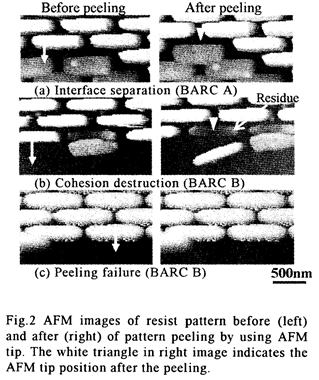

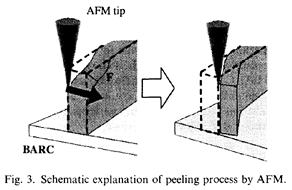

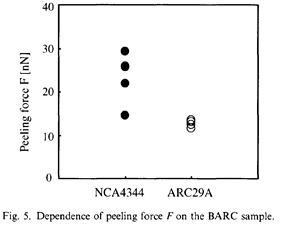

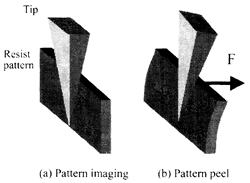

| 2007-10. | Kazutoshi Kurano, Takahiro Kishioka, Yoshiomi Hiroi, Takuya Ohashi, Akira Kawai “Peeling analysis of ArF resist pattern on BARC by using AFM” J. Photopolymer Science and Technology, 20(6), 825-826 (2007). (IF: 0.835) [abstract] |

| 2007-11. | Kazutoshi Kurano, Takahiro Kishioka, Yoshiomi Hiroi, Takuya Ohashi, Akira Kawai “Deformation analysis of ArF resist pattern by using AFM” J. Photopolymer Science and Technology, 20(6), 827-828 (2007). (IF: 0.835) [abstract] |

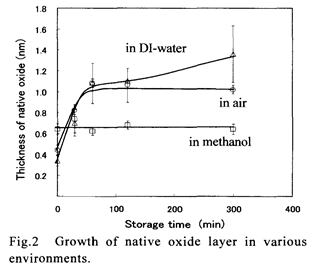

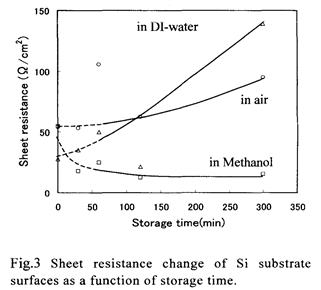

| 2007-12. | Harumitsu Kubota, Akira Kawai “Native oxide growth on Si(100) surface in liquid environment” J. Photopolymer Science and Technology, 20(6), 823-824 (2007). (IF: 0.835) [abstract] |

2006年

8報

| 2006- 1. | Akira Kawai, Takahiro Moriuchi, Takayoshi Niiyama, Takahiro Kishioka, Daisuke Maruyama,

Yasushi Sakaida, Takashi Matsumoto “Adhesion improvement of ArF resist pattern depending on BARC material” Microelectronic Engineering, 83, 659-662 (2006). (IF: 1.398) [abstract] |

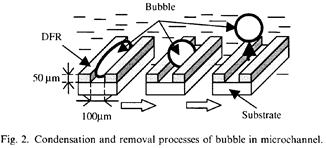

| 2006- 2. | Akira Kawai, Hotaka Endo, Tomotaka Ariga “Condensation mechanism of microbubbles depending on DFR pattern design” Microelectronic Engineering, 83, 1167-1169 (2006). (IF: 1.398) [abstract] |

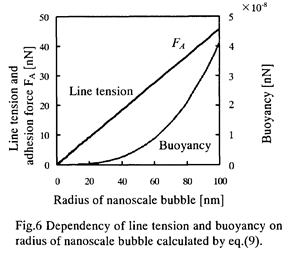

| 2006- 3. | Akira Kawai, Kenta Suzuki “Removal mechanism of nano-bubble with AFM for immersion lithography” Microelectronic Engineering, 83, 655-658 (2006). (IF: 1.398) [abstract] |

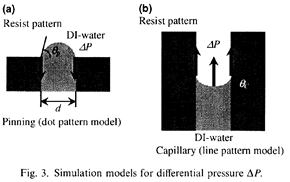

| 2006- 4. | Takayoshi Niiyama, Akira Kawai “Micro wetting system by controlling pinning and capillary forces” Microelectronic Engineering, 83, 1280-1283 (2006). (IF: 1.398) [abstract] |

| 2006- 5. | 安江孝夫、河合 晃 「走査型プローブ顕微鏡によるシリコン酸化膜の経時絶縁破壊特性」 日本表面科学会誌、27 (4) 49-54 (2006). [abstract] |

| 2006- 6. | Mitsuru Sato and Akira Kawai “Topcoat characterization for immersion lithography by fluoric acid etching on silicon substrate” J. Photopolymer Sci. Technol., 19(5), 601-611 (2006). (IF: 1.222) [abstract] |

| 2006- 7. | Takayoshi Niiyama and Akira Kawai “Formation factors of watermark for immersion lithography” Jpn. J. Appl. Phys. 45, 5383-5387 (2006). (IF: 1.222) [abstract] |

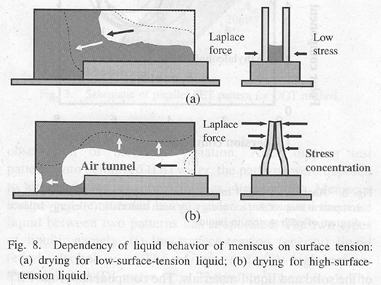

| 2006- 8. | Akira Kawai and Kenta Suzuki “Effect of low surface tension liquid on pattern collapse analyzed by observing dynamical meniscus observation” Jpn. J. Appl. Phys., 45, 5429-5434 (2006). (IF: 1.222) [abstract] |

2005年

5報

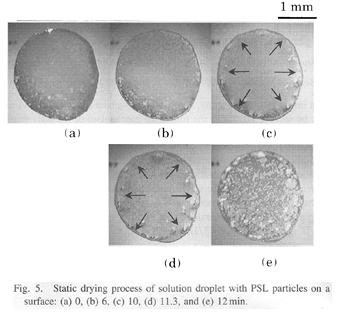

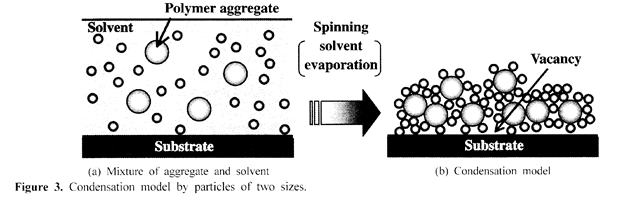

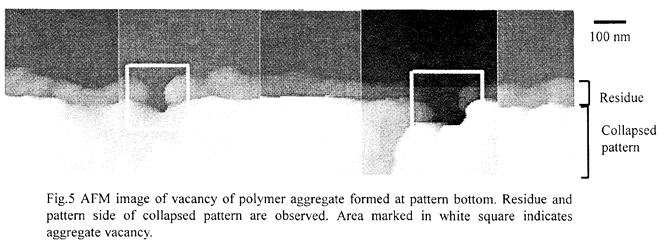

| 2005- 1. | Atsushi Ishikawa, Akira Kawai “Condensation of Nano-Size Polymer Aggregates by Spin Drying” J. Adhesion and Interface, vol.6 (1) 7-10 (2005). (IF: 1.024) [abstract] |

| 2005- 2. | Akira Kawai “Condensation behavior of nanoscale bubbles on ArF excimer resist surface analyzed by atomic force microscope” J. Photopolymer Sci. Technol., 18(3), 349-354 (2005). (IF: 0.859) [abstract] |

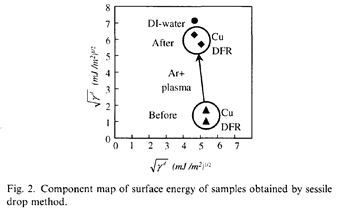

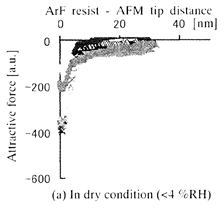

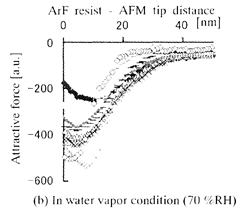

| 2005- 3. | Takayoshi Niiyama, Akira Kawai “Interaction analysis of DI-water / Air / ArF resist system using atomic force microscope” J. Photopolymer Sci. Technol., 18(3), 373-380 (2005). (IF: 0.859) [abstract] |

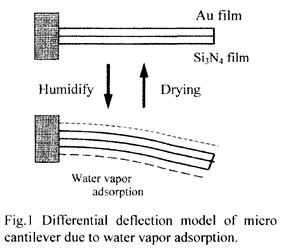

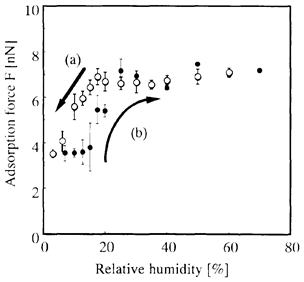

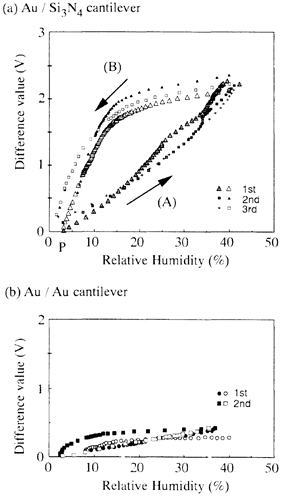

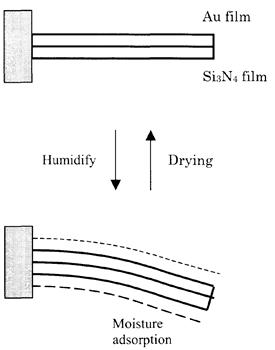

| 2005- 4. | Akira Kawai, Takahiro Moriuchi “Deflection analysis of micro cantilever due to water vapor adsorption” J. Photopolymer Sci. Technol., 18 (3), 681-682 (2005). (IF: 0.859) [abstract] |

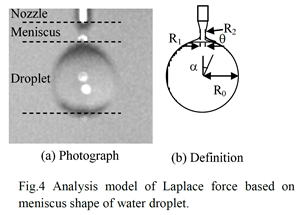

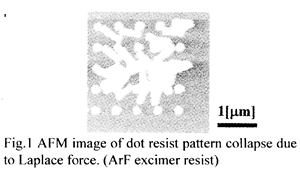

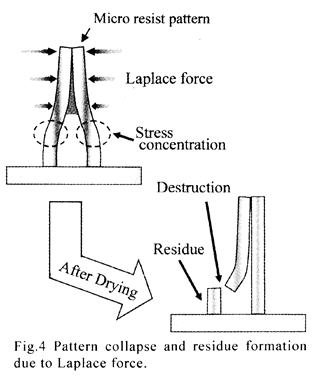

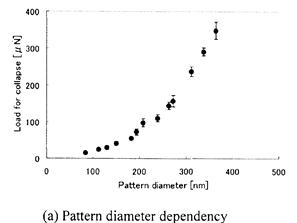

| 2005- 5. | Akira Kawai, Kenta Suzuki “Dot pattern collapse due to Laplace force analyzed by dynamical meniscus model” J. Photopolymer Sci. Technol., 18(3), 679-680 (2005). (IF: 0.859) [abstract] |

2004年

12報

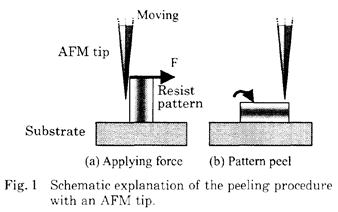

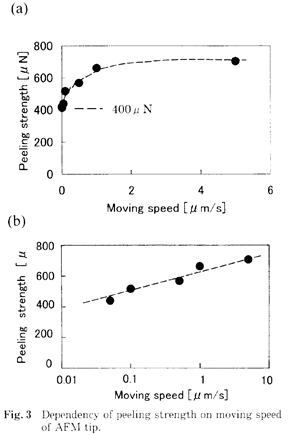

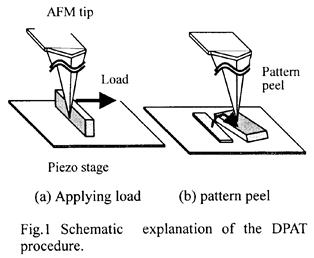

| 2004- 1. | Akira Kawai “Influence of moving speed of AFM tip on peeling strength of micro resist pattern” J. Adhes. Soc. Technol. 40, 11-13 (2004). [abstract] |

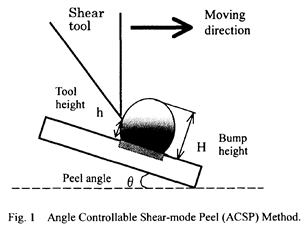

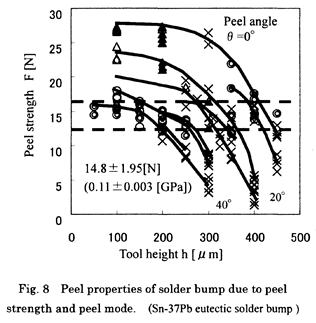

| 2004- 2. | 河合 晃、大澤義征 「角度制御型シェアモード剥離法」 Microjoining and Assembly Technology in Electronics, p77-82 (2004). [abstract] |

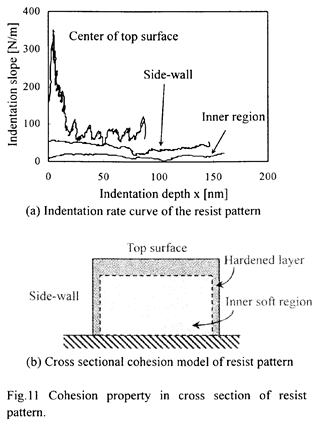

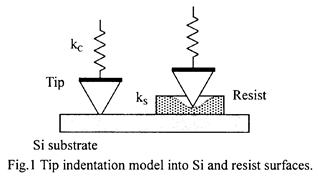

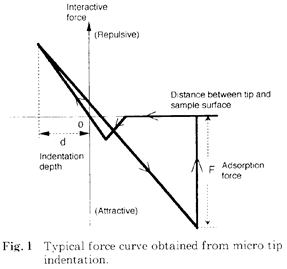

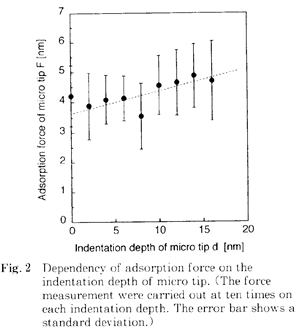

| 2004- 3. | Akira Kawai “Cohesion property of resist pattern surface analyzed by tip indentation method” J. Photopolymer Sci. Technol., 17(3), 441-448 (2004). (IF: 1.024) [abstract] |

| 2004- 4. | Takayoshi Niiyama and Akira Kawai “Interaction force analysis of resist film surface in water vapor” J. Photopolymer Sci. Technol., 17(3), 453-456 (2004). (IF: 1.024) [abstract] |

| 2004- 5. | Atsushi Ishikawa, Makoto Sakata and Akira Kawai “Meniscus analysis in micro gap during liquid drying process” J. Photopolymer Sci. Technol., 17(3), 457-460 (2004). (IF: 1.024) [abstract] |

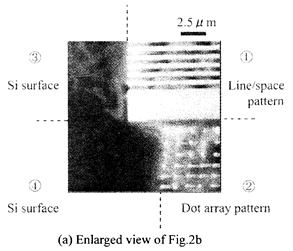

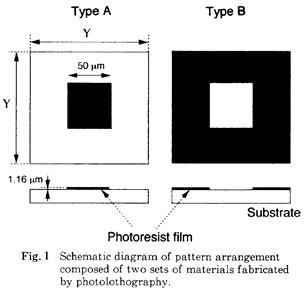

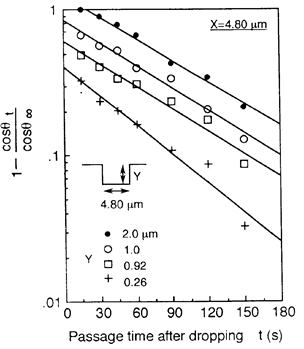

| 2004- 6. | Akira Kawai, Masahito Hirano and Takayoshi Niiyama “Analysis for drying behavior of rinse water depended on resist pattern arrangement” J. Photopolymer Sci. Technol., 17(3), 461-464 (2004). (IF: 1.024) [abstract] |

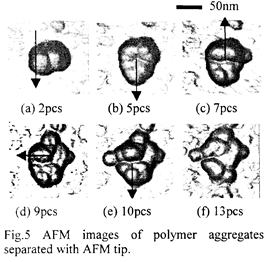

| 2004- 7. | Atsushi Ishikawa, Takashi Tanji and Akira Kawai “Cohesion property of polymer aggregate depending on hardening treatment” J. Photopolymer Sci. Technol., 17(1), 99-102 (2004). (IF: 1.024) [abstract] |

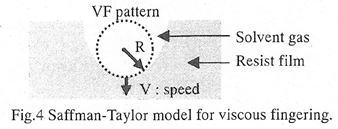

| 2004- 8. | Akira Kawai, Akihiko Seki and Hotaka Endo “Viscous finger pattern formed in photoresist film during heat treatment” J. Photopolymer Sci. Technol., 17(1), 103-104 (2004). (IF: 1.024) [abstract] |

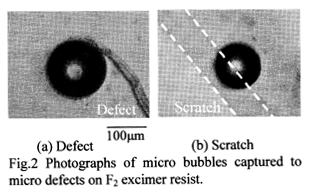

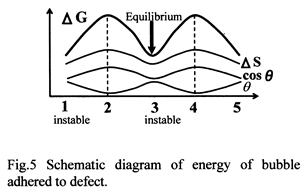

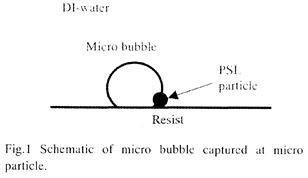

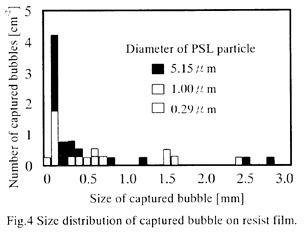

| 2004- 9. | Hotaka Endo and Akira Kawai “Micro bubbles captured at micro defect on resist film” J. Photopolymer Sci. Technol., 17(1), 105-106 (2004). (IF: 1.024) [abstract] |

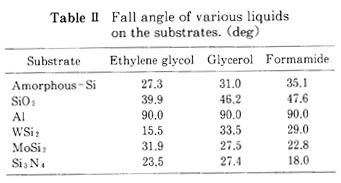

| 2004-10. | Masaki Yamanaka, Akira Okada and Akira Kawai “Pinning effect of microliquid drop on geometrical complex substrates composed with different surface energy materials” J. Vac. Sci. & Technol. B22(6), Nov/Dec 3525-3527 (2004). (IF: 1.341) [abstract] |

| 2004-11. | Atsushi Ishikawa, Takashi Tanji, Akira Kawai “Determination of Young's modulus of polymer aggregate based on Hertz theory” J. Photopolymer Sci. Technol., 17(5), 715-718 (2004). (IF: 1.024) [abstract] |

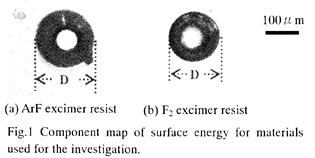

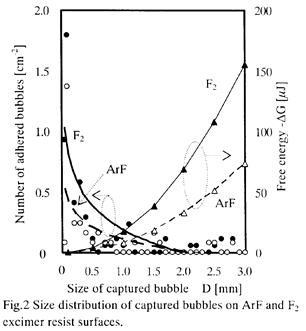

| 2004-12. | Hotaka Endo, Akira Kawai “Adhesion mechanism of micro bubbles on ArF and F2 excimer resists” J. Photopolymer Sci. Technol., 17(5), 713-714 (2004). (IF: 1.024) [abstract] |

2003年

10報

| 2003- 1. | Akira Kawai, Daisuke Inoue “Effect of Thermal Stress on Peel Property of Line Resist Pattern Analyzed by Atomic Force Microscope (AFM)” J. Adhes. Soc. Technol. 39, 107-109 (2003). [abstract] |

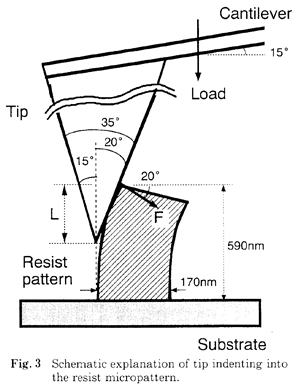

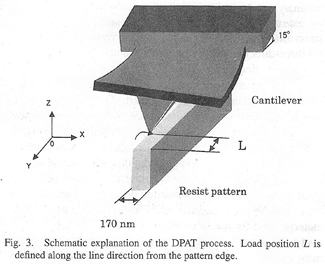

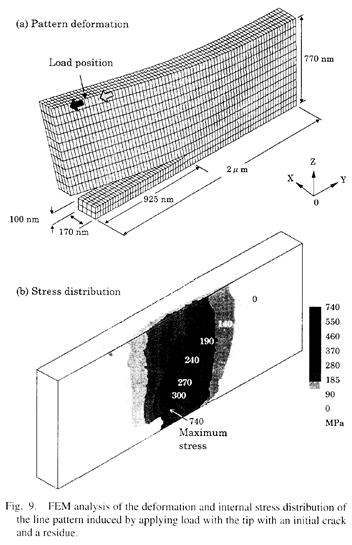

| 2003- 2. | Daisuke Inoue, Akira Kawai “Peeling Analysis of Resist line Pattern of 170nm Width Due To Crack Formation by using Atomic Force Microscope Tip” Surface and Coating Technology, 169-170, pp.311-315 (2003). (IF: 1.410) [abstract] |

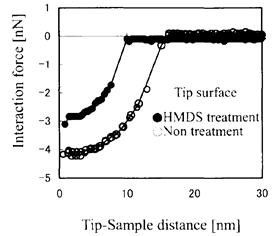

| 2003- 3. | Akira Kawai, Daisuke Inoue “Van der Waals interaction between Si surface and micro tip apex treated with hexamethyldisilazane (HMDS)” J. Adhes. Soc. Technol. 39, 255-258 (2003). [abstract] |

| 2003- 4. | Akira Kawai “Cohesion property of resist micro pattern analyzed by using atomic force microscope (AFM)” J. Photopolymer Sci. Technol., 16(3), 381-386 (2003). (IF: 1.062) [abstract] |

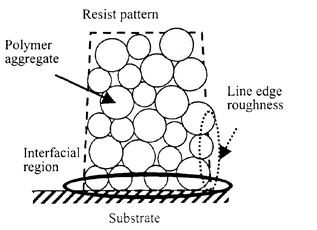

| 2003- 5. | Naotaka Kubota, Tomohiko Hayashi, Takeshi Iwai, Hiroshi Komano, Akira Kawai “Advanced resist design using AFM analysis for ArF lithography” J. Photopolymer Sci. Technol., 16(3), 467-474 (2003). (IF: 1.062) [abstract] |

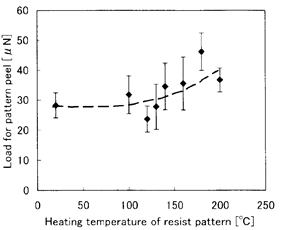

| 2003- 6. | Akira Kawai “Adhesion of ArF Excimer Resist Pattern Depending on Heating Temperature Analyzed by Atomic Force Microscope” J. Adhes. Soc. Technol. 39, 423-425 (2003). [abstract] |

| 2003- 7. | Akira Kawai, Yuji Sawanaga “Condensation control of micro particles by charge deposition method” J. Photopolymer Sci. Technol., 16(5), 669-670 (2003). (IF: 1.062) [abstract] |

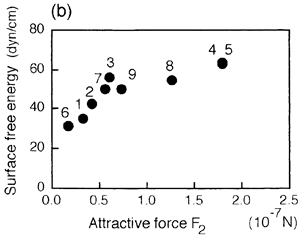

| 2003- 8. | Akira Kawai, Junko Kawakami “Characterization of SiO2 surface treated by HMDS vapor and O2 plasma with AFM tip” J. Photopolymer Sci. Technol., 16(5), 665-668 (2003). (IF: 1.062) [abstract] |

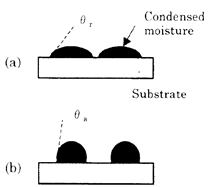

| 2003- 9. | Masahito Hirano, Akira Kawai “Adhesion of AFM tip to resist surface due to Laplace force” J. Photopolymer Sci. Technol., 16(5), 663-664 (2003). (IF: 1.062) [abstract] |

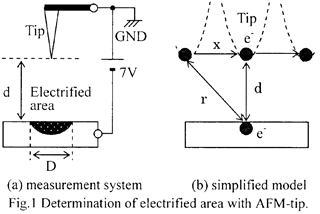

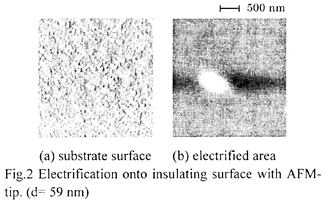

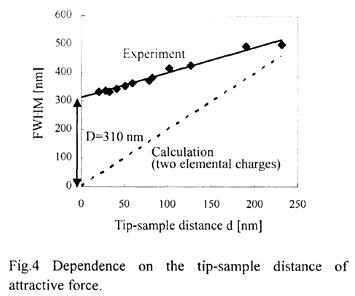

| 2003-10. | Takayoshi Niiyama, Yuji Sawanaga, Akira Kawai “Determination of electrified area formed by AFM lithography” J. Photopolymer Sci. Technol., 16(5), 661-662 (2003). (IF: 1.062) [abstract] |

2002年

9報

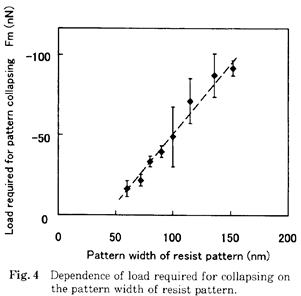

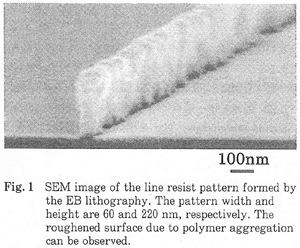

| 2002- 1. | Akira Kawai, Takato Abe “Analysis of Pattern Collapse of Electron Beam Resist Ranging from 60 to 152 nm Width with Atomic Force Microscope Tip” J. Adhesion Soc. Japan, 38 16-19 (2002). [abstract] |

| 2002- 2. | 河合 晃 「探針の吸着力測定による水蒸気の凝縮性解析」 日本接着学会誌、38, 50-53 (2002). [abstract] |

| 2002- 3. | 河合 晃 「水蒸気吸着に伴う微細カンチレバーの撓み変位の解析」 日本接着学会誌、38, 169-172 (2002). [abstract] |

| 2002- 4. | Akira Kawai “Adhesion and Cohesion Properties of Dot Resist Patterns Ranging from 84 to 364 nm Diameter Analyzed by Direct Peeling Method with Atomic Force Microscope Tip” J. Photopolymer Science & Technology, 15(1), 121-126 (2002). (IF: 1.062) [abstract] |

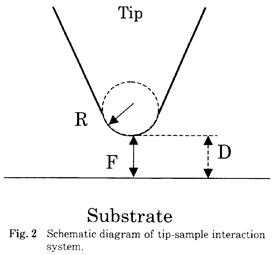

| 2002- 5. | Akira Kawai, Daisuke Inoue “Van der Waals Interaction between Polymer Aggregates and Substrate Surface Analyzed by Atomic Force Microscope (AFM)” J. Photopolymer Science & Technology, 15(1), 127-132 (2002). (IF: 1.062) [abstract] |

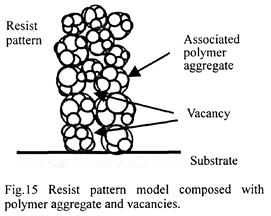

| 2002- 6. | Akira Kawai “Cohesion Property of Polymer Aggregates in Resist Pattern Analyzed by Atomic Force Microscope (AFM)” J. Photopolymer Science & Technology, 15(3), 371-376 (2002). (IF: 1.062) [abstract] |

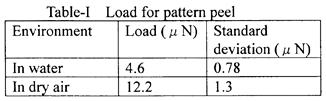

| 2002- 7. | Akira Kawai, Daisuke Inoue “Peeling Property of Resist Pattern in Water Analyzed by Atomic Force Microscope” J. Photopolymer Science & Technology, 15(5), 757-758 (2002). (IF: 1.062) [abstract] |

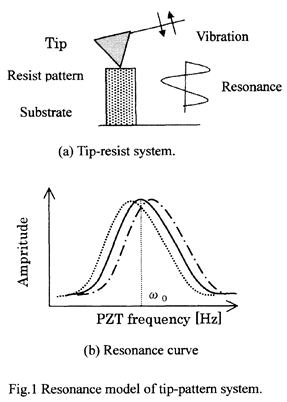

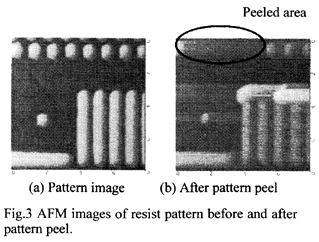

| 2002- 8. | Akira Kawai “Resist Pattern Peel due to Resonance Effect of Micro Tip” J. Photopolymer Science & Technology, 15(5), 759-760 (2002). (IF: 1.062) [abstract] |

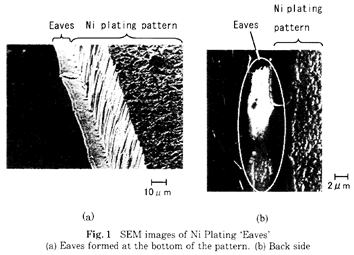

| 2002- 9. | Hideaki Yoshida, Tadashi Nakamura, Yoshiaki Kawakami, Akira Kawai “Establishment of Eaves Forming Model by Analysis of the Interface Energies at the Threefold of Cu/DFR/Ni Plating Solution” J. Adhesion Soc. Japan, 38, 413-419 (2002). [abstract] |

2001年

12報

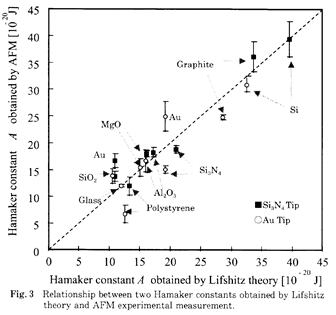

| 2001- 1. | 河合 晃、堀口博司 「原子間力顕微鏡を用いた微細探針と無機固体表面間のHamaker定数解析」 日本接着学会誌、37, 146-149 (2001). [abstract] |

| 2001- 2. | Akira Kawai, Norio Moriike “Analysis of Pattern Collapse of ArF Excimer Laser Resist by Direct Peeling Method with Atomic Force Microscope Tip” Microelectronic Engineering, vol.57-58, pp683-692 (2001). (IF: 0.705) [abstract] |

| 2001- 3. | Akira Kawai, Norio Moriike “Adhesion and Cohesion Analysis of ArF/SOR Resist Patterns with Microtip of Atomic Force Microscope (AFM)” J. Photopolymer Science and Technology, 14(4), 507-512 (2001). (IF: 1.062) [abstract] |

| 2001- 4. | Akira Kawai, Takato Abe “Direct Measurement of Resist Pattern Adhesion on the Surface with Silane-coupling Treatment by Atomic Force Microscope (AFM)” J. Photopolymer Science and Technology, 14(4), 513-518 (2001). (IF: 1.062) [abstract] |

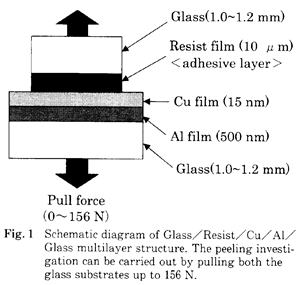

| 2001- 5. | 原 朋敬、小泉延恵、河合 晃 「Glass/レジスト/Cu/Al/Glass多層構造の破壊特性解析」 日本接着学会誌、37, 303-308 (2001). [abstract] |

| 2001- 6. | 阿部貴人、河合 晃 “原子間力顕微鏡(AFM)を用いた線幅60nmのラインレジストパターンの弾性解析” 日本接着学会誌、37, 353-357 (2001). [abstract] |

| 2001- 7. | Akira Kawai, Norio Moriike “Resist Hardening by Electron Beam Irradiation Analyzed by Atomic Force Microscope” J. Photopolymer Science and Technology, 14(5), 751-752 (2001). (IF: 1.062) [abstract] |

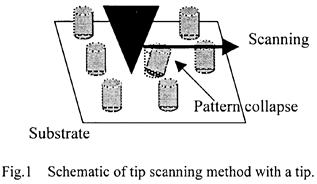

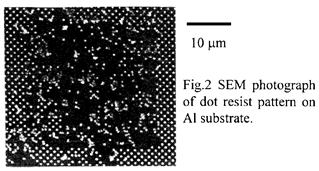

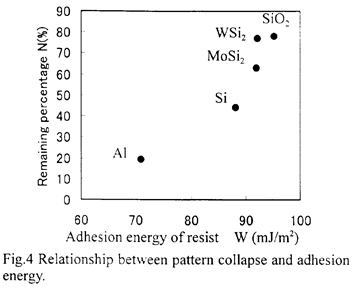

| 2001- 8. | Akira Kawai “Collapse of Dot Patterns Formed on Various Substrates analyzed by Tip Scanning Method” J. Photopolymer Science and Technology, 14(5), 723-724 (2001). (IF: 1.062) [abstract] |

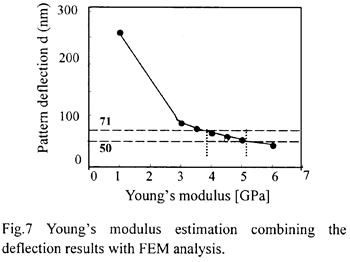

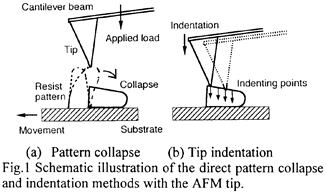

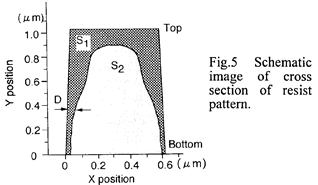

| 2001- 9. | Akira Kawai, Yoshihisa Kaneko “Estimation of Young’s Modulus of Resist Pattern by using Atomic Force Microscope” J. Photopolymer Science and Technology, 14(5), 731-734 (2001). (IF: 1.062) [abstract] |

| 2001-10. | Akira Kawai, Yoshiaki Kawakami “DUV Hardened Layer of Resist Dot Pattern Detected by Tip Indentation Method” J. Photopolymer Science and Technology, 14(5), 749-750 (2001). (IF: 1.062) [abstract] |

| 2001-11. | Akira Kawai, Yoshihisa Kaneko “Fatigue Property of Resist Micro Pattern Analyzed by Atomic Force Microscope Tip” J. Photopolymer Science and Technology, 14(5), 701-702 (2001). (IF: 1.062) [abstract] |

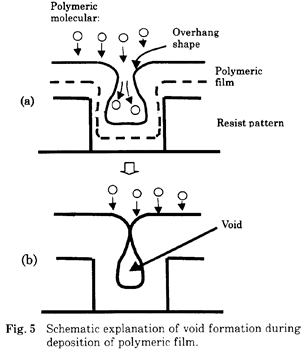

| 2001-12. | 磯部 亮、河合 晃 「微細周期パターン上へのプラズマ重合膜の堆積特性」 日本接着学会誌、37, 433-436 (2001). [abstract] |

2000年

8報

| 2000- 1. | Akira Kawai “Collapse Behavior of Organic Dot-Pattern Analyzed by the Tip Indentation Method” J. Adhesion Soc. Japan, 36, 23-27 (2000). [abstract] |

| 2000- 2. | 河合 晃、川上喜章 “原子間力顕微鏡(AFM)を用いた微細探針走査法によるフォトレジスト微細パターンの接着性解析” 日本接着学会誌、36, 2-9 (2000). [abstract] |

| 2000- 3. | Akira Kawai, Yoshihisa Kaneko “Analysis of Resist Pattern Collapse by Direct Peeling Method with Atomic Force Microscope Tip” Jpn. J. Appl. Phys., 39, 1426-1429 (2000). (IF: 1.157) [abstract] |

| 2000- 4. | 河合 晃 “固体表面での微細探針の吸着力解析” 日本接着学会誌、36, 131-135 (2000). [abstract] |

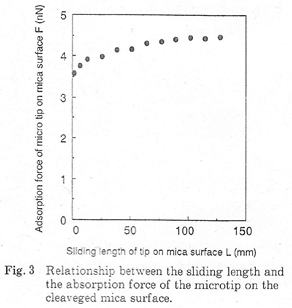

| 2000- 5. | 河合 晃 “マイカへき開表面での微細探針の摩耗に伴う吸着力変化” 日本接着学会誌、36, 172-175 (2000). [abstract] |

| 2000- 6. | 森池教夫、河合 晃 “原子間力顕微鏡を用いた一括破壊試験法による有機ドットパターンの付着挙動解析” 日本接着学会誌、36, 295-301 (2000). [abstract] |

| 2000- 7. | 森池教夫、河合 晃 “原子間力顕微鏡を用いた微細レジストドットパターンの疲労解析” 日本接着学会誌、36, 404-407 (2000). [abstract] |

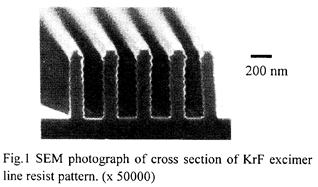

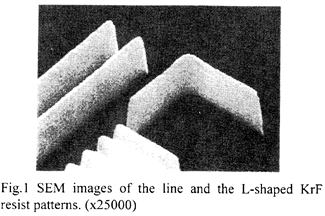

| 2000- 8. | Akira Kawai “Collapse Behavior of KrF Resist Line Pattern Analyzed with Atomic Force Microscope Tip” Jpn. J. Appl. Phys., 39, 7044-7048 (2000). (IF: 1.058) [abstract] |

1999年

2報

| 1999- 1. | Akira Kawai “Collapse Behavior of Micro Resist Pattern Analyzed by Tip Indentation Method with Atomic Force Microscope” J. Vac. Sci. & Technol. B17, 1090-1093 (1999). (IF: 1.687) [abstract] |

| 1999- 2. | 河合 晃 「Cu/Al多層膜構造の破壊強度に及ぼすAl自然酸化膜の影響」 日本接着学会誌、35, 558-561 (1999). [abstract] |

1998年

5報

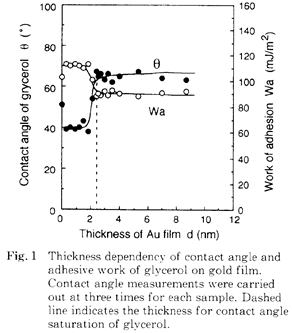

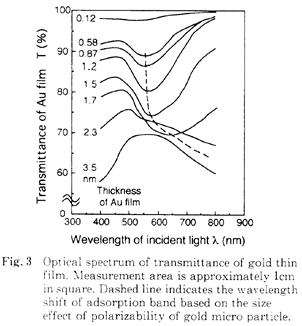

| 1998- 1. | 河合 晃 「10nm以下のAu薄膜の成長挙動と接触角変化」 日本接着学会誌、34, 209-213 (1998). [abstract] |

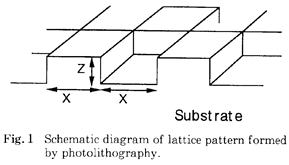

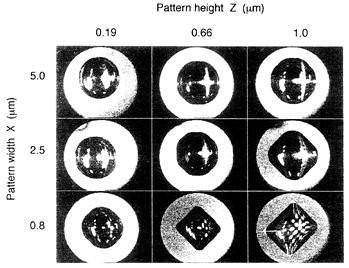

| 1998- 2. | 河合 晃 「ミクロンサイズの格子型基板を用いた液滴平面形状の制御」 日本接着学会誌、34, 226-228 (1998). [abstract] |

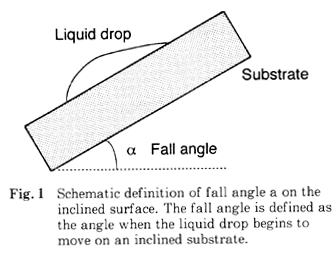

| 1998- 3. | Akira Kawai “Characterization of Fall Angle of Water Drop based on Surface Energy Components” J. Adhesion. Soc. Japan, 34, 191-193 (1998). [abstract] |

| 1998- 4. | 河合 晃、岡田 彰 「異種材料で構成された格子状基板上での液滴の接触角」 日本接着学会誌、34, 22-25 (1998). [abstract] |

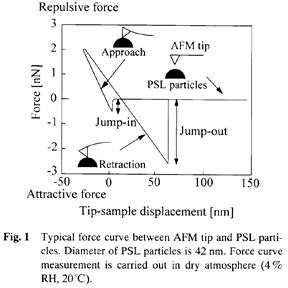

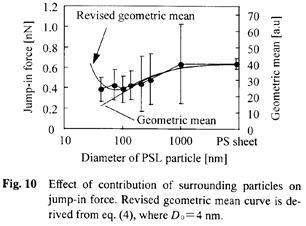

| 1998- 5. | 堀口博司、河合 晃 「AFM探針とポリスチレンラテックス(直径42nm~1μm)凝集粒子間の付着力解析 -DMT理論に基づく微粒子系の相互作用力の補正式-」 日本表面科学会誌、19, 491-497 (1998). [abstract] |

1997年

4報

| 1997- 1. | 河合 晃 「原子間力顕微鏡(AFM)によるフォトレジスト膜表面の摩擦挙動解析(周期パターンの歪検出方式)」 日本接着学会誌、33, 465-471 (1997). [abstract] |

| 1997- 2. | 河合 晃、芦田安立 「AFM微細探針によるAu表面の弾性および吸着特性」 日本接着学会誌、33, 395-397 (1997). [abstract] |

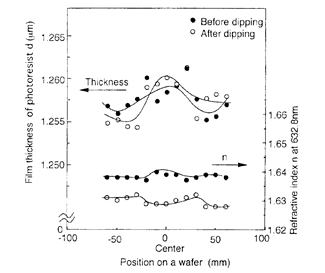

| 1997- 3. | Wataru Wakamiya, Makoto Hirayam, Akihiko Yasuoka, Akira Kawai “Refractive Index Distribution in Photoresist Thin Film Formed by the Spin Coating Method” Jpn. J. Appl. Phys., 36, L1622-L1624 (1997). (IF: 1.261)[abstract] |

| 1997- 4. | 河合 晃、小泉延恵 「溶剤蒸発に伴うレジスト膜の粘性指状変形と接着性」 日本接着学会誌、33, 434-437 (1997). [abstract] |

1996年

6報

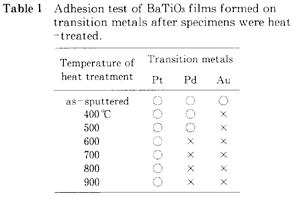

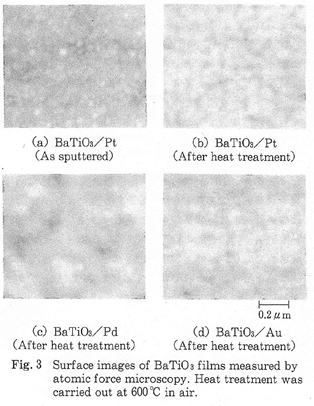

| 1996- 1. | 河合 晃、熊谷武司、高田雅介 「遷移金属薄膜上に形成したBaTiO3薄膜の熱処理時の接着挙動」 日本接着学会誌、32, 404-409 (1996). [abstract] |

| 1996- 2. | Akira Kawai “Measuring the Thermal Properties of Photoresist Thin Films Using Atomic Force Microscopy” Thin Solid Films, 273, 308-311 (1996). (IF: 1.890) [abstract] |

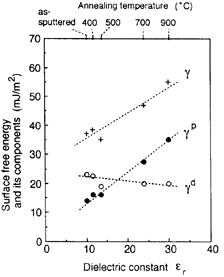

| 1996- 3. | 河合 晃 「スパッタリングで形成したAuおよびPtの大気中放置に基づく表面自由エネルギー変化」 日本接着学会誌、32, 39-43 (1996). [abstract] |

| 1996- 4. | Akira Kawai, Takeshi Kumagai and Masasuke Takata “Correlation between Surface Free Energy and Dielectric Constant of BaTiO3 Thin Film” J. Adhesion Society of Japan, 32, 221-223 (1996). [abstract] |

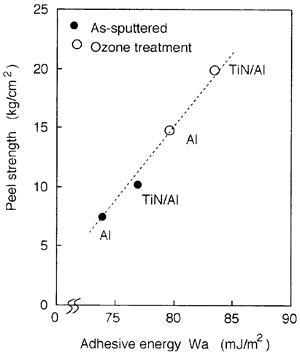

| 1996- 5. | Wataru Wakamiya, Makoto Hirayama, Akihiko Yasuoka and Akira Kawai “Adhesion Improvement of Photoresist on TiN/Al Multilayer by Ozone Treatment” Jpn. J. Appl. Phys., 35, L1227~L1229 (1996). [abstract] |

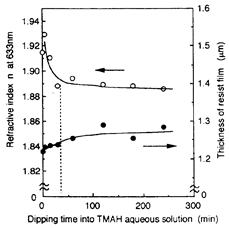

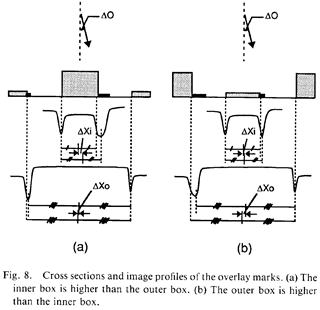

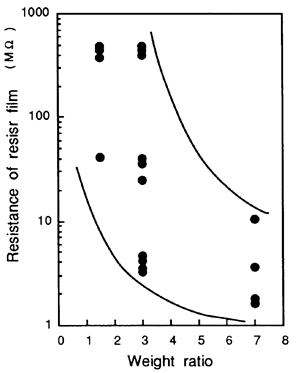

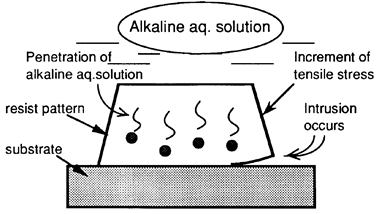

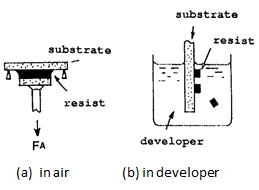

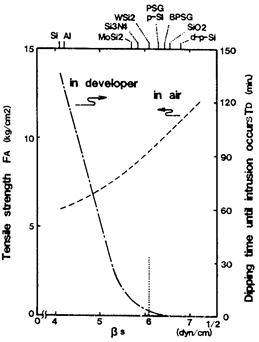

| 1996- 6. | 若宮 亙、平山 誠、安岡晶彦、河合 晃 「フォトレジスト膜へのアルカリ水溶液の浸透と接着性」 日本接着学会誌、32, 294-297 (1996). [abstract] |

1995年

11報

| 1995- 1. | 永田一志、河合 晃 「Al薄膜の表面粗さとレジスト微細パターンの接着性」 日本接着学会誌、31, 44-48 (1995). [abstract] |

| 1995- 2. | 永田一志、河合 晃 「フォトレジスト膜の残留歪みと接着性に及ぼす溶剤の効果」 日本接着学会誌、31, 187-191 (1995). [abstract] |

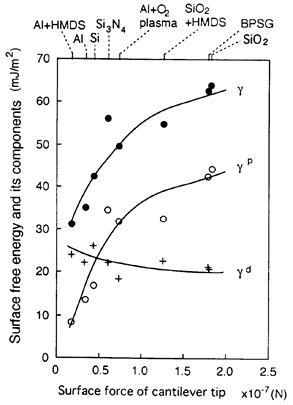

| 1995- 3. | 河合 晃 「原子間力顕微鏡により検出した薄膜の表面力と表面自由エネルギー成分との相関」 日本接着学会誌、31, 237-240 (1995). [abstract] |

| 1995- 4. | Akira Kawai “Spreading of Water Drop on Geometrical Rough Surface Formed by Photolithography” J. Adhesion Society of Japan, 31, 92-94 (1995). [abstract] |

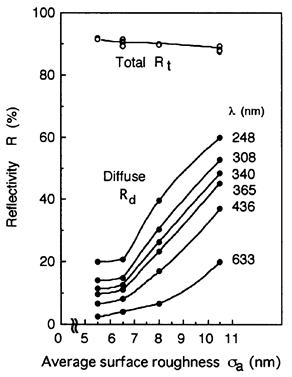

| 1995- 5. | Hitoshi Nagata, Atsumi Yamaguchi and Akira Kawai “Characterization of Thin-Film Interference Effect due to Surface Roughness” Jpn. J. Appl. Phys. 34, 3754-3758 (1995). [abstract] |

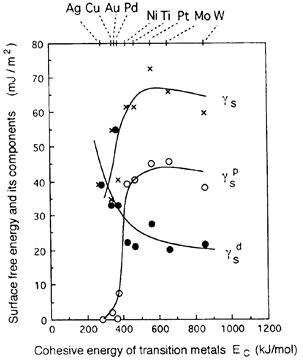

| 1995- 6. | 河合 晃、熊谷武司、高田雅介 「接触角法により測定した遷移金属薄膜の表面自由エネルギーの分散および極性成分」 日本接着学会誌、31, 307-311 (1995). [abstract] |

| 1995- 7. | 河合 晃 「表面結露法により検出したAl表面の有機汚染層とフォトレジストパターンの接着性」 日本接着学会誌、31, 354-359 (1995). [abstract] |

| 1995- 8. | Akira Kawai “Adhesion of Resist Micropatterns during Drying after Water Rinse” Jpn. J. Appl. Phys., 34, L1093-L1094 (1995). [abstract] |

| 1995- 9. | Akira Kawai “Adhesion of Micro Window Pattern Formed by Photolithography” J. Adhesion Society of Japan, 31, 360-362, (1995). [abstract] |

| 1995-10. | 永田一志、河合 晃 「TMAH水溶液中でレジスト膜に発生した環境応力亀裂」 日本接着学会誌、31, 452-457 (1995). [abstract] |

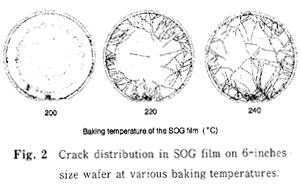

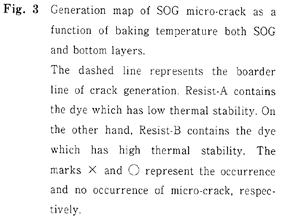

| 1995-11. | 永田一志、河合 晃 「レジスト膜上のスピンオンガラス膜に発生する微細亀裂」 日本接着学会誌、31, 498-501 (1995). [abstract] |

1994年

9報

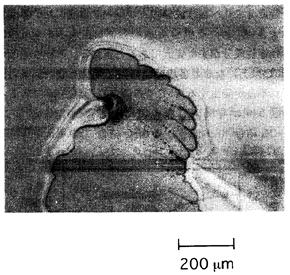

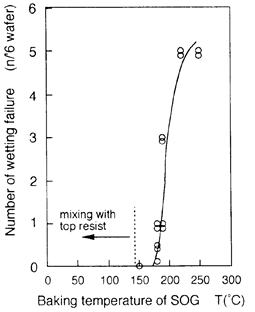

| 1994- 1. | 河合 晃、永田一志 「有機スピンオンガラス上でのフォトレジストの濡れ不良」 日本接着学会誌、30, 582-585 (1994). [abstract] |

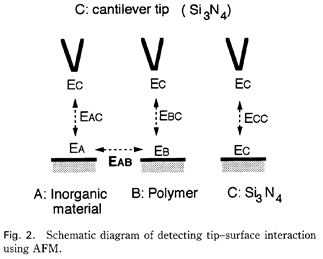

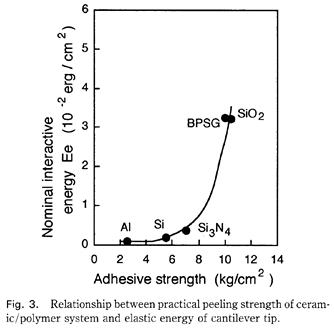

| 1994- 2. | Akira Kawai, Hitoshi Nagata and Masasuke Takata, “Measurement Method of Adhesion Strength between Inorganic Materials and Polymer by Using Atomic Force Microscopy” J. Ceramic Society of Japan, 102, 1102~1104 (1994). [abstract] |

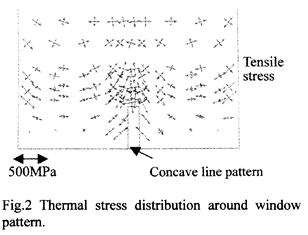

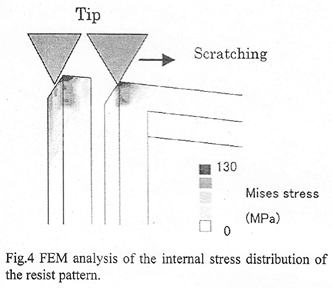

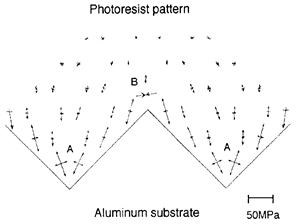

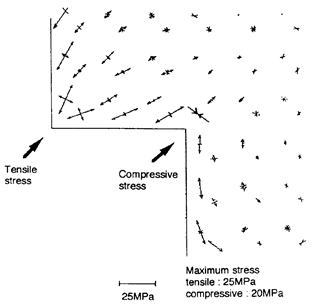

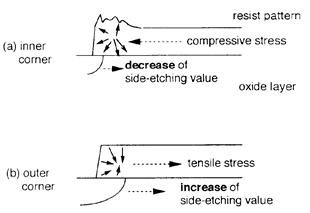

| 1994- 3. | 河合 晃、永田一志、高田雅介 「レジスト微細パターン内の熱応力分布と接着特性」 日本接着学会誌、30, 549-554 (1994). [abstract] |

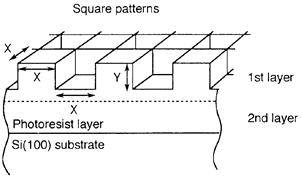

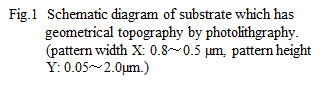

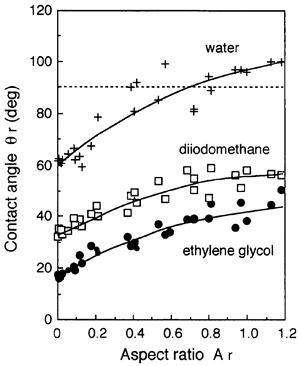

| 1994- 4. | Akira Kawai, Hitoshi Nagata, “Wetting Behavior of Liquid on Geometrical Rough Surface Formed by Photolithograpy” Jpn. J. Appl. Phys. 33, L1283-L1285 (1994). [abstract] |

| 1994- 5. | Akira Kawai, Hitoshi Nagata, “Wetting Failure of Photoresist on Spin-On-Glass (SOG) Substrate by Spin Coating” Jpn. J. Appl. Phys. 33, L1355-L1357 (1994). [abstract] |

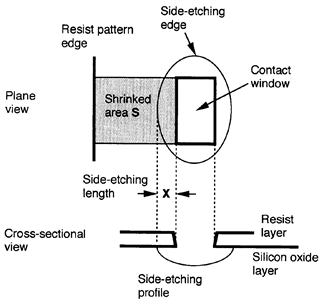

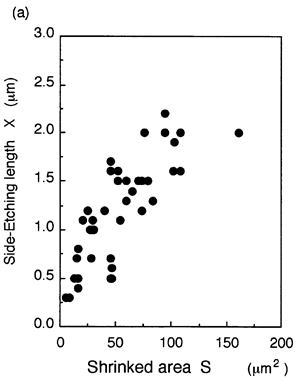

| 1994- 6. | Akira Kawai, Hitoshi Nagata and Masasuke Takata, “Shrinkage Effect of Local Area of Polymer Film on Adhesion Behavior” Jpn. J. Appl. Phys. 33, L973-L974 (1994). [abstract] |

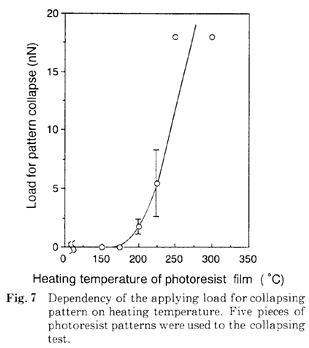

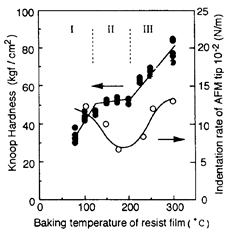

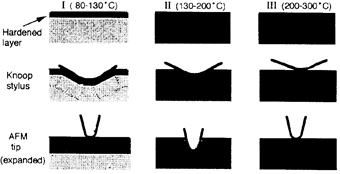

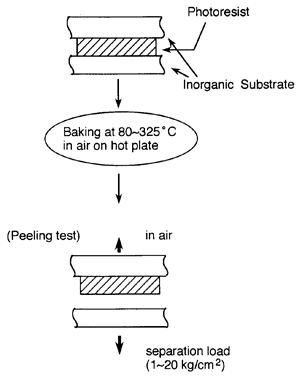

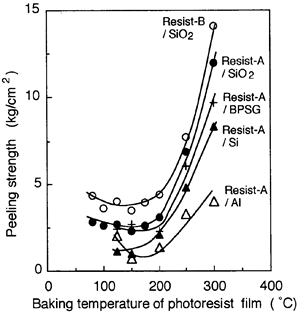

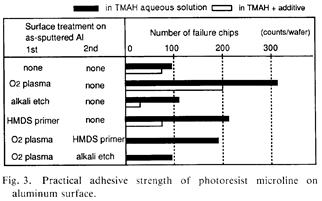

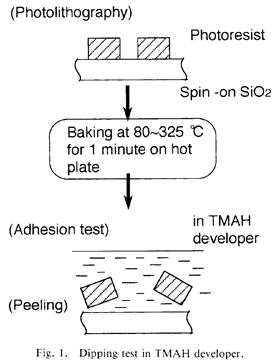

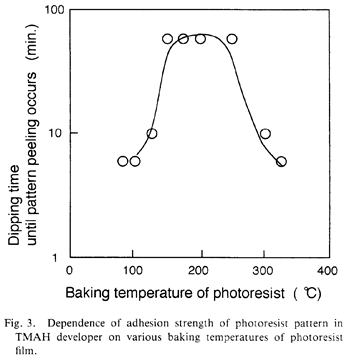

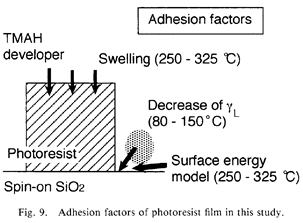

| 1994- 7. | Akira Kawai, Hitoshi Nagata, Hiroaki Morimoto and Masasuke Takata, “Adhesion of Photoresist Pattern Baked at 80 to 325℃ to Inorganic Solid Surface” Jpn. J. Appl. Phys. 33, L146-L148 (1994). [abstract] |

| 1994- 8. | Hitoshi Nagata, Akira Kawai, Hiroaki Morimoto and Masasuke Takata, “Blister Formation at photoresist-Substrate Interface” Jpn. J. Appl. Phys. 33, 3635-3639 (1994). [abstract] |

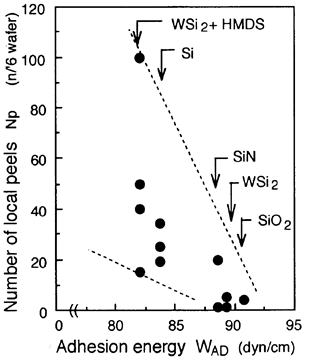

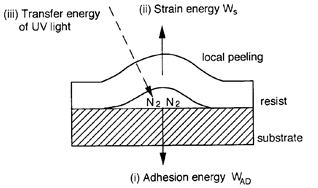

| 1994- 9. | Akira Kawai, Hitoshi Nagata, Hiroaki Morimoto and Masasuke Takata, “Local Peeling of Photoresist Film during Ultraviolet Light Exposure” Jpn. J. Appl. Phys. 33, L149-L151 (1994). [abstract] |

1983-1993年

8報

| 1993- 1. | Akira Kawai, Hitoshi Nagata and Masasuke Takata “Dependency of Adhesion Behavior on Thermal Stress Distribution in Photoresist Micropatterns” Jpn. J. Appl. Phys. 32, 1020-1024 (1993). [abstract] |

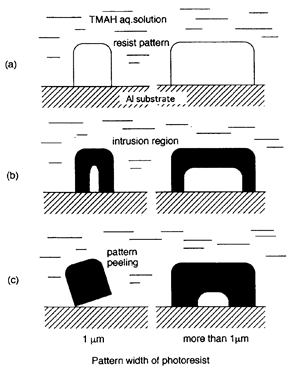

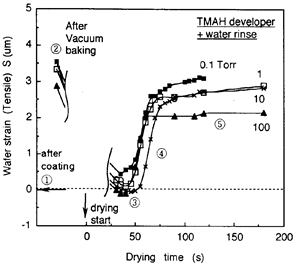

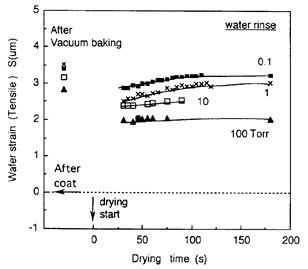

| 1992- 1. | Akira Kawai, Hitoshi Nagata and Masasuke Takata “Adhesion of Photoresist Micropattern to Aluminum Substrate in Alkaline Aqueous Solution” Jpn. J. Appl. Phys. 31, 1933-1939 (1992). [abstract] |

| 1992- 2. | Akira Kawai, Hitoshi Nagata and Masasuke Takata “Adhesion of Photoresist Pattern Baked at 80 to 325℃ in Tetramethyl-ammonium- hydroxide Aqueous Solution” Jpn. J. Appl. Phys. 31, 3725-3730 (1992). [abstract] |

| 1992- 3. | Akira Kawai, Hitoshi Nagata and Masasuke Takata “Characterization of Surface Energetic Behavior by Atomic Force Microscopy” Jpn. J. Appl. Phys. 31, L977-L979 (1992). [abstract] |

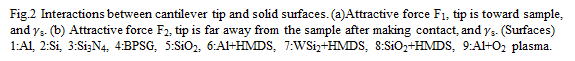

| 1992- 4. | Akira Kawai, Jinzou Watanabe, Hitoshi Nagata and Masasuke Takata, “Dependence of Offset Error on Overlay Mark Structures in Overlay Measurement” Jpn. J. Appl. Phys. 31, 385-390 (1992). [abstract] |

| 1991- 1. | Akira Kawai, Hitoshi Nagata, Haruhiko Abe and Masasuke Takata, “Adhesion between Photoresist and Inorganic Substrate” Jpn. J. Appl. Phys. 30, 121-125 (1991). [abstract] |

| 1989- 1. | Hitoshi Nagata and Akira Kawai, “Characteristics of Adhesion between Photoresist and Inorganic Substrate” Jpn. J. Appl. Phys. 28, 2137-2141 (1989). [abstract] |

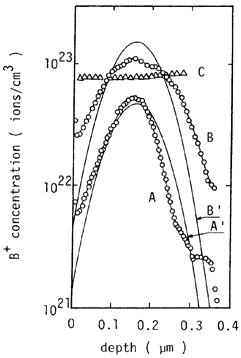

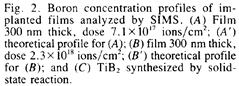

| 1983- 1. | Shoichi Okamoto, Akira Kawai, Kenkichiro Kobayashi, Masasuke Takata, TsutomuYamashita and Shiro Yamashita, “Synthesis of TiB2 by High-Dose Implantation of Boron Ions Titanium Films” J. American Ceramic Soc., 66, c-78 (1983). [abstract] |

abstract

2017年 2報

| 2017- 1. | Natsumi Yagi and Akira Kawai "Three-Dimensional Analysis of Liquid Propagation at Microchannel Junction using ESEM", J. Photopolymer Science and Technology, 30(6), 709-714 (2017) |

|

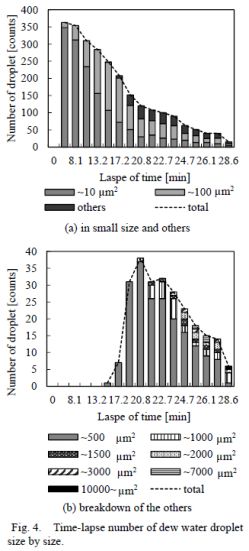

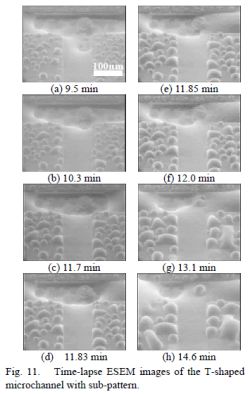

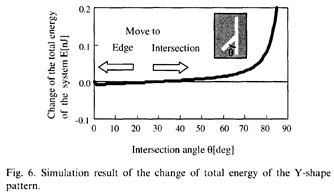

| [abstract] The three-dimensional wetting phenomena in a T-shaped microchannel made of a SU-8 photoresist accompanying with a pillar sub-pattern are analyzed by using an environmental scanning electron microscopy (ESEM). By lowering the sample temperature in the ESEM chamber at constant the H2O pressure, the water condensation occurs under H2O dew point and the liquid propagation in the microchannel can be observed. The experimental results show that the pinning angle of water flow at T-junction is 58 degrees in the T-shaped microchannel. In the case of the T-shaped microchannel with the sub-pattern, it is found that the pinning angle becomes low by adhering the water around the sub-pattern. These results can realize to the smooth flow at the channel junction without any water trapping for the three-dimensional microfluidic devices. Keywords: ESEM, Microchannel, Pillar-pattern, Three-dimensional analysis |

||

|

|

|

| 2017- 2. | Katsuaki Yamane and Akira Kawai "Application to Artificial Skin of Double Cone Tube Made of Acrylic Resin Formed by Micro Stereolithography" J. Photopolymer Science and Technology, 30(3), 345-350 (2017) |

|

| [abstract] A functional double cone tube (DCT) array with gas trapping and high durability is developed in the application of artificial skin. A stereo-lithography system is employed to fabricate DCT made of acrylic resin. In an aqueous solution, a certain amount of gas can be trapped in the tube due to capillary force balance. Under applying an external load, internal stress is effectively released at the interface between top and base cones. In the tactile sensing investigation, softness and tackiness senses as an artificial skin are felt. Keywords: Artificial skin, Micro stereo-lithography, Acrylic resin, Double cone tube (DCT), Gas storage, Stress distribution |

||

|

|

|

2016年 3報

| 2016- 1. | Hiroki Nakano, Kenta Takahashi, Akira Kawai, "Negative Pattern Formation in Positive Resist Layer by EB / UV Hybrid Lithographys", J. Photopolymer Science and Technology, 29(4), 603-606 (2016) in perss. |

|

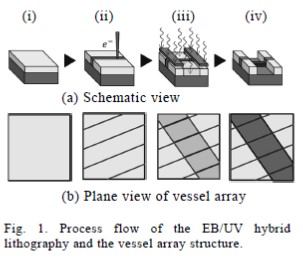

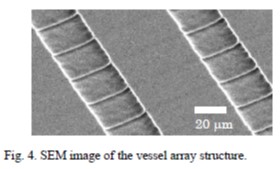

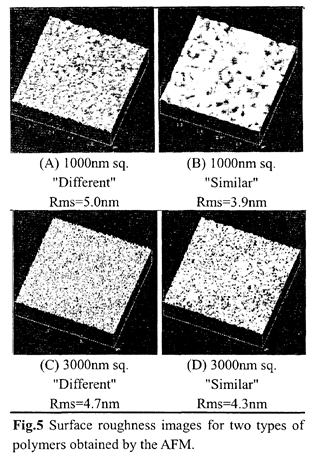

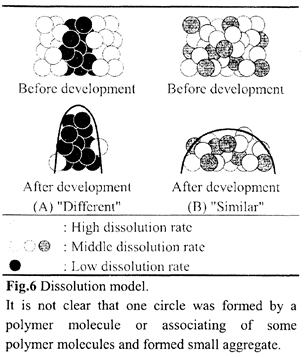

| [abstract] By the combination of EB (electron beam) pattern irradiation and UV (ultraviolet) exposure processes, negative tone pattern can be formed in a positive type resist film. It is well known that a novolac resin based resist film can be crosslinked by thermal and EB irradiation processes. By changing the EB irradiation and UV light exposure doses, a dissolution resistance of the resist film to TMAH (tetramethylammoniumhydroxide) alkaline aqueous solution can be controlled. As the result, the EB/UV hybrid lithography is effective for the fabrication of difference height patterns in a single resist layer. A dose response characteristic of a resist film is determined. A roughness of resist pattern in EB/UV hybrid lithography is also discussed. As an application, a micro square vessel array is fabricated used for a bioelec tronic field Keywords: electron beam lithography, photolithography, photoresist, atomic force microscopy (AFM), surface roughness, EB/UV hybrid lithography |

||

|

|

|

| 2016- 2. | Hodaka Shirataki, Akira Kawai, "In-situ Monitoring of TMAH Developer Intrusion into Resist Film by C-V Method", J. Photopolymer Science and Technology, 29(6), 817-822 (2016) |

|

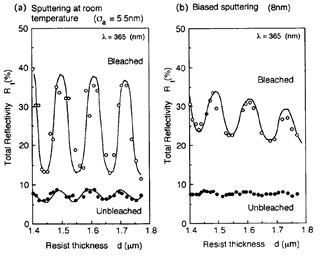

| [abstract] The TMAH developer (2.38 wt% aqueous solution) intrusion into a resist film is analyzed by the typical current-voltage (C-V) method. As well known device structure, Metal / Insulator / Semiconductor (MIS) structure is employed, and a resist film (novolak resin base) is adopted to an insulator material. During the TMAH developer dropping on the Au mesh electrode, an increase of the capacitance and a parallel shift towards a negative gate bias voltage region in a C-V curve can be clearly observed. At the first stage of dropping, these signal changes in C-V curve are relatively large. Refractive index of the resist film slightly increases after the TMAH developer dropping, which reflects the condensation of polymer resin due to the TMAH developer intrusion. A contact angle decrease of the TMAH developer after dropping is also monitored. A spreading coefficient cS of TMAH developer decreases gradually as the time elapse. Particularly, the capacitance change clearly indicates the intrusion of the TMAH developer as the function of a time elapses. These dynamic measurements of the intrusion will be effective to analyze the liquid intrusion mechanisms into polymer materials. Keywords: liquid intrusion, TMAH developer, photoresist, MIS structure, C-V curve, dielectric constant, refractive index, contact angle, spreading coefficient, in-situ monitoring |

||

|

|

|

| 2016- 3. | Natsumi Yagi, Akira Kawai, "Effect of Sub-Pattern on Guiding Liquid Propagation at Microchannel Junction", J. Photopolymer Science and Technology, 29(6), 833-834 (2016) |

|

| [abstract] Keywords: sub-pattern, ESEM, microchannel, liquid flow, Young-Laplace equation, pinning effect |

||

|

||

|

|

|

2014年 2報

| 2014- 1. | Yako Kunii, Akira Kawai "Tactile senses control by contacting a human finger with micro resist pattern arrangements" J. Photopolym. Sci. Technol., 27 (6) 691-694 (2014) |

|

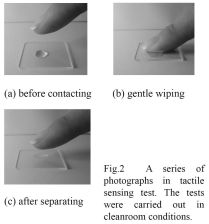

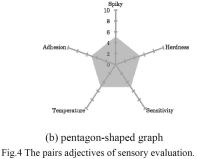

| [abstract] A functional micro resists structures with tactile characters of the human are developed due to sweat, sebum and water influence. A new method of tactilesensory evaluation with the pentagon-shaped graph is employed. It is found that the micro pattern acts to wet and to feel smooth and comfortable by immersing some kinds of liquids. By the surface energy analysis, the tactile sensory evaluation can be explained at the point of wetting nature. Keywords : human tactile sensitivity, lithography, micro pattern array, touch panel plate |

||

|

|

|

|

|

|

| 2014- 2. | Akira Kawai, Shogo Ohtani "Frequencydispersion of permittivity of SU-8 resist thin film" J. Photopolym. Sci. Technol., 27 (6) 711-712 (2014) |

|

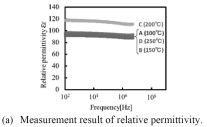

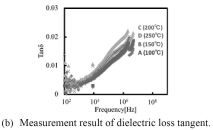

| [abstract] Permittivity of a SU-8 (3050) resist film baked at 100, 150, 200 and 250℃ is characterized by a typical capacitance method in the frequency range from 100Hz to 5MHz. The permittivity is relatively constant in the frequency range, but slight dependency on baking temperature can be confirmed. The dielectric loss tangent of resist film increases gradually up to 0.03 but relatively low. The typical dielectric properties of resist material can be confirmed experimentally, which indicates an application possibility of resist material as an electronic device component material. Keywords: photoresist, SU-8, permittivity, dielectric loss, frequency response |

||

|

|

|

|

||

2013年 7報

| 2013- 1. | Akira Kawai “Electrification on Condensation Surface of Micro Particles with Atomic Force Microscope (AFM)” J. Photopolymer Science and Technology, 26(6), 705-706 (2013). |

|

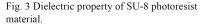

| [abstract] Keyword : atomic force microscope, micro particle, polystyrene latex, electrified image |

||

|

|

|

| 2013- 2. | Yuta Noguchi, Akira Kawai “Local Heating System Integrated with Platinum Micro Heater and Photopolymer Microfluidic Channel” J. Photopolymer Science and Technology, 26(6), 713-716 (2013). |

|

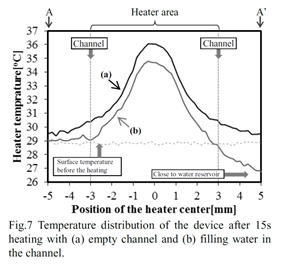

| [abstract] Local heating system composed with micro heater and microfluidic channel is designed and fabricated. Micro heater made of platinum film is formed on a slide glass by radio-frequency magnetron sputtering and lift-off processes. Microfluidic channel is designed to surround the micro heater. A SU-8 epoxy-based negative photoresist is employed as micro channel material and patterned by lithography process. The micro heater has ability to heat over 350℃at an electric power of 3.12W. Local heating property is evaluated by applying DC electric power. Heating area decreases 61.5% for micro channel filled with water by comparison with empty channel. Temperature of water in the micro channel is rise up 3.5℃ and heat absorption, which is estimated about 275.3μJ. The microfluidic channel with water is an effective method for local hearing. The local heating system with integration of micro heater and channel is one candidate which can apply to various fields such as biological and biomedical tools. Keywords : local heating system, micro heater, microfluidic channel, SU-8 photoresist |

||

|

|

|

| 2013- 3. | Kazutoshi Otsuka, Kenta Takahashi, Akira Kawai “Fabrication of Micro Tube Array by Combining Positive with Negative Type Photoresists due to Solubility Difference in Developer” J. Photopolymer Science and Technology, 26(6), 717-720 (2013). |

|

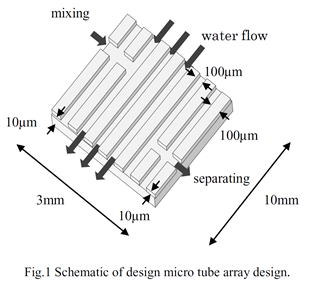

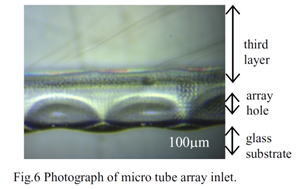

| [abstract] The micro tube array in triple layer structure is constructed due to solubility difference phenomena. The triple layers are fabricated by photolithography process with i-line and SU-8 photoresists. The first and third layers are formed with SU-8 photoresist process. The second layer is formed by i-line photoresist process. Both i-line photoresist and unexposed SU-8 photoresist can be dissolved by dipping in the SU-8 developer at the same time. The exposed region of the SU-8 photoresist film is remained. The SU-8 photoresist film is formed in micro tube array structure. The shape of micro tube array is fabricated in rectangle of 10.0mm length and 3.05mm width. The array hole is formed 103μm width and 8.96μm thickness. By applying this process, unique structures of microfluidic system such as artificial capillary blood tube can be realized. Keywords : photoresist, solubility difference, capillary tube, micro tube, array structure, SU-8 photoresist |

||

|

|

|

| 2013- 4. | Yosuke Sakurai, Kenta Takahashi, Akira Kawai “Liquid Penetration Control of Photoresist/Perfluorosulfonic Acid (PFSA) Double Layer Structure by Hydrophobic Treatment” J. Photopolymer Science and Technology, 26(6), 727-732 (2013). |

|

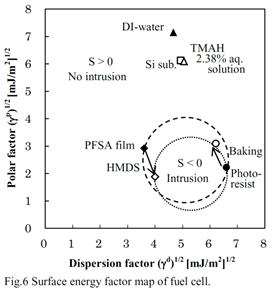

| [abstract] Silicon-based micro fuel cells are considerable interest for micro electromechanical system (MEMS) devices. Micro pattern fabrication by photolithography and etching process is effective for minimization of fuel cells. It is known that the photolithography process is difficult to employ for an electrolyte of perfluorosulfonic acid (PFSA) film due to swelling and peeling under wet process. In order to prevent the problems, a hexamethyldisilazane (HMDS) primer treatment is employed on the interface of photoresist/PFSA. Consequently, photoresist/PFSA double layer structure can be formed on the Si substrate with no defect formation. The double layer structure is selectively etched by reactive ion etching (RIE) process with CF4 gas in order to fabricate the micro pattern of PFSA film. The effect of HMDS primer treatment is observed as a hydrophobic effect by an analysis of wetting energy. The PFSA film with HMDS primer treatment should prevent to penetrate the liquid into the PFSA film under wet process. Keywords: perfluorosulfonic acid (PFSA), photolithography, hexamethyldisilazane (HMDS), reactive ion etching (RIE), adhesion property |

||

|

|

|

|

||

| 2013- 5. | Yuta Noguchi, Kenta Takahashi, Akira Kawai “Micro Pinhole Formation in Photoresist Multilayer Structure controlled with Hydrophilic Treatment” J. Photopolymer Science and Technology, 26(6), 739-744 (2013). |

|

| [abstract] The pinhole formation in photoresist multilayer structure acts as a critical defect for device fabrication. The purpose of this study is pinhole prevention by hydrophilic treatment and analysis of pinhole formation mechanism in terms of surface free energy. A SU-8 photoresist top layer is spin-coated on a SU-8 bottom layer as simplest multilayer structure. Pinholes are formed on bottom layer with no-treatment, however, pinholes cannot be observed when bottom layer is treated by hydrophilic process. Subsequently, the surface free energy and spread coefficients of each SU-8 layer are evaluated. Because the absolute value of spreading coefficient Stop is small relatively in case of no-treatment, the pinning phenomenon can be caused by contaminants. A triple point, bottom layer, liquid top layer and air, appears at the pinning area. Air cannot intrude into interface between top-bottom layers due to the spreading coefficient “Sair>0”. Consequently, the pinhole expansion phenomenon would be dominated by tensional force and viscous-elasticity of liquid top layer. By hydrophilic treatment, surface free energy of bottom layer increases drastically, therefore the pinning phenomenon is prevented because of “Stop<<0”. Keywords: pinhole, pinning, SU-8 photoresist, multilayer structure, hydrophilic treatment, surface free energy, spreading coefficient |

||

|

||

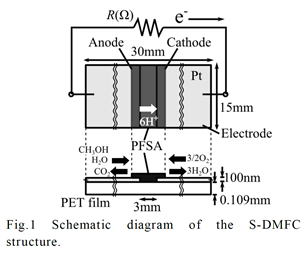

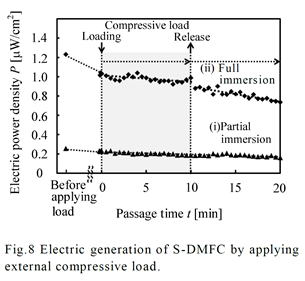

| 2013- 6. | Yosuke Sakurai, Daisuke Tanaka, Shunsuke Ohata, Akira Kawai “Fabrication and Durability of Single Chip Micro Direct Methanol Fuel Cell (SC-μDMFC) by Photolithography Process” J. Photopolymer Science and Technology, 26(6), 751-756 (2013). |

|

| [abstract] Single chip micro direct methanol fuel cell (SC-μDMFC) is attractive as a chip scale power source for micro electromechanical system (MEMS) devices. A multilayer structure is commonly employed for the fuel cell. The durability of SC-μDMFC should be mostly affected by interface energy. In this study, SC-μDMFC is fabricated by employing a photoresist / Pt electrode / PFSA film multilayer structure. The fabrication of SC-μDMFC (chip size of 2.0mm×2.0mm ×500μm) is succeeded without any film peeling. Consequently, maximum output power of 0.07μW is obtained. The film peeling of SC-μDMFC is also analyzed by the interface energy method. As a result, several layers of weak adhesion are predicted. However, the film peeling could not occur by the contribution of the other mechanical adhesion factors. The experimental results indicate the durability of the SC-μDMFC. Keywords : direct methanol fuel cell (DMFC), multilayer structure, photolithography, perfluorosulfonic acid (PFSA), adhesion property, spreading analysis |

||

|

|

|

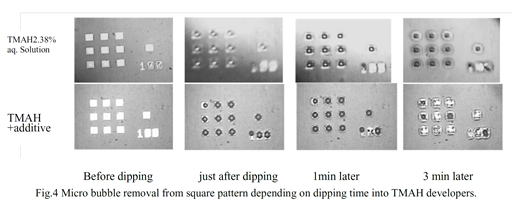

| 2013- 7. | Kenta Takahashi, Akira Kawai “Effect of Low Surface Tension Developer on Micro Bubble Removal from Resist Square Window Pattern” J. Photopolymer Science and Technology, 26(6), 765-768 (2013). |

|

| [abstract] In pattern developmemt, a removal property of bubbles formed on a concave window pattern made of DFR (dry film resist) is characterized. The sizes of the DFR window pattern are 100μm square and 50μm height. The fundamental factors of removal property can be explained by means of interaction analysis among interfacial energies. The experimental results obtained are analyzed based on the free energy balance model thermodynamically. The factor of micro bubble removal from the DFR window pattern is discussed for the suitable micro pattern fabrication. By adding a hydrophobic nonionic surfactant, both polar and dispersion components of surface energy of the developer clearly decrease. These components change act to decrease surface tension of the developer. The effectiveness of low surface tension developer on the removal property of micro bubble can be explained based on surface energy. Keywords : DFR, micro bubble, surface energy, window pattern, surfactant, TMAH developer |

||

|

||

2012年 4報

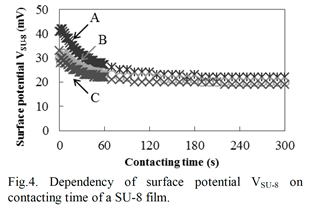

| 2012- 1. | Yuta Noguchi, Akira Kawai “Surface Stability of SU-8 film for Accurate Biopotential Detection” J. Photopolymer Science and Technology, 25(6), 719-722 (2012). |

|

| [abstract] Biopotential is important and sensitive information in order to monitor and control growth condition for living cells. For detecting biopotential change accurately, a stable biocompatible polymer film is required. In this study, a stable surface of a SU-8 film is characterized, and it is possible for applying to a cover material of electrode surface or an element of a biological implanted device. Surface potential VSU-8 of a SU-8 film is measured by making a metallic electrode contact. As a standard equilibrium, VSU-8 indicates exponential decreasing to reach at +21mV. Biopotential Vbio of plant cells indicates large potential change for 10 to 42mV range. This potential change means an individualistic signal of living cells. By combination of a SU-8 film and living cells, it is capable of obtaining accurate and effective data. Keywords : SU-8 resist, plant cells, surface potential, biopotential, biocompatible material |

||

|

|

|

| 2012- 2. | Yosuke Sakurai, Akira Kawai “Mechanical Stress Effect on Ionic Conductivity of Perfluorosulfonic Acid (PFSA) Film by Photolithography” J. Photopolymer Science and Technology, 25(6), 723-727 (2012). |

|

| [abstract] Direct Methanol Fuel Cell (DMFC) consists of a perflurosulfonic acid (PFSA) electrolyte is attractive as a portable power source. It is possible to fabricate a DMFC array by dividing a PFSA film into micro pieces by photolithography. In this regard, it is known that photoresist film causes significant compressive and tensile stress generation in an underlying layer. Then it is needed to control preparation condition of photoresist film formed on a PFSA film. The effect of compressive load in a PFSA film is observed as enhancement of electro motive force. By applying compressive load to a PFSA film, proton ionic conductivity would be enhanced. On the other hand, a tensile load acts to decrease electro motive force. Therefore photoresist pattern shape should be designd effectively in order to enhance proton ionic conductivity of PFSA film. Keywords : stress, photoresist film, retention property, perflurosulfonic acid (PFSA), Direct Methanol Fuel Cell (DMFC) |

||

|

|

|

|

||

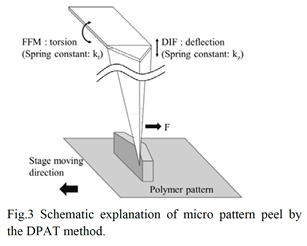

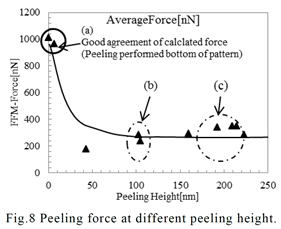

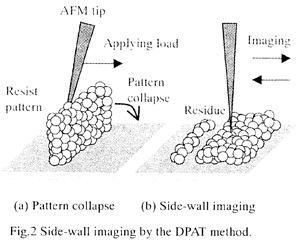

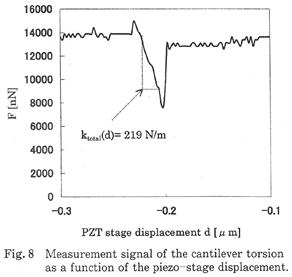

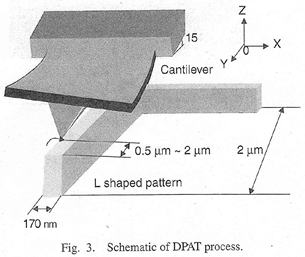

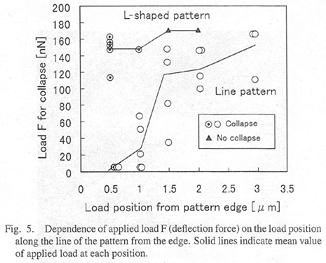

| 2012- 3. | Takashi Aiba, Akira Kawai “Micro Cantilever Motion in Micro Pattern Peeling by DPAT Method” J. Photopolymer Science and Technology, 25(6), 729-733 (2012). |

|

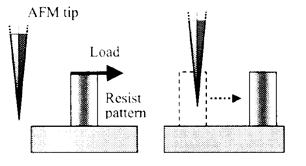

| [abstract] DPAT (Direct Peeling by using AFM tip) method provides direct measurement of a peeling force of micro-structure. A peeling force of micro polymer pattern at different peeling height is analyzed. When a cantilever is made a contact with a bottom of pattern, peeling force and displacement of cantilever are larger than in those of pattern top. The cantilever motion is analyzed peeling phenomena in different peel height. The peeling force of pattern is determined to around 1μN. The peeling force applying at pattern bottom reflects the adhesion force. The effectivity and accuracy of the DPAT method is discussed. Keyword : polymer micro pattern, atomic force microscope, direct peeling by using AFM tip (DPAT), adhesion force, cohesion failure, interface failure |

||

|

|

|

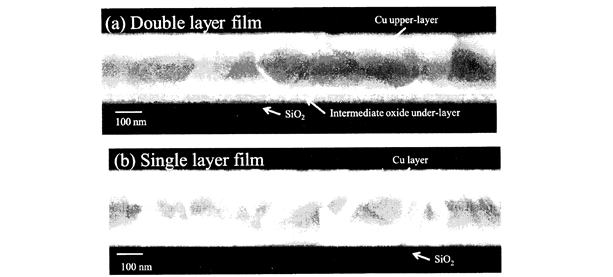

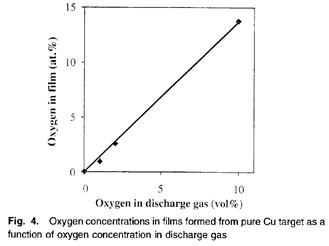

| 2012- 4. | Satoru Mori, Akira Kawai “Interfacial Microstructure of a Double-layer Cu Film Consisting of an Under-layer Deposited on SiO2 Substrate in Ar-10 vol% O2 and an Upper-layer Deposited in Pure Ar” J. Adhesion Soc. Japan, 48(1), 10-16 (2012). |

|

| [abstract] Interfacial microstructure of a double-layer Cu film, composed of an under-layer deposited on SiO2,in Ar-10voI% O2 followed by an upper layer deposited in pure Ar, was investigated for thin film conductor tracks for large and high-definition liquid crystal displays. The layer deposited in Ar-10vo1% O2 has fine-grain, and contains Cu and Cu2O. Detailed analysis shows the interface between the under-layer and SiO2 substrate isn't flat, but concavity and convexity. Addition of oxygen to the discharge gas generates Cu2O in the under-layer. Cu2O dissolves in the SiO2, and forms CuO-SiO2 eutectic. The dissolution of Cu2O in SiO2 must increase anchor effect and the adhesive strength. Keywords : copper, film, sputtering, oxygen, LCD |

||

|

||

2011年 2報

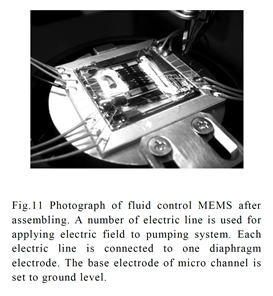

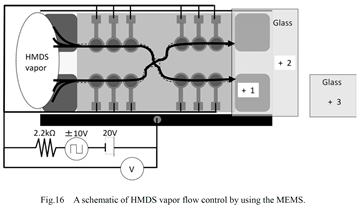

| 2011- 1. | Akira Kawai “Fluid Control MEMS constructed with Polymer Materials” J. Photopolymer Science and Technology, 24(5), 587-593 (2011). |

|

| [abstract] A polymer material indicates higher durability and resistance properties against to reactive gases,acid and alkaline solutions. Fluid control MEMS (micro electro mechanical systems) with micro diaphragm pumping system used for reactive gas control is constructed. A resist film made of novolac resin as a diaphragm material is employed. An Au/Si/resist multilayer structure as a diaphragm of 1mm diameter is formed by optical lithography and anisotropic wet etching techniques. A micro channel structure of 50μm width is also fabricated by employing a polymer thick film. The mechanical strength of a diaphragm is tested by applying static load using a probe system.By applying 20V bias between diaphragm and base electrodes,Coulomb attractive force acts to operate the diaphragm motion. As the fluid flow control, a silane-coupling vapor gas of HMDS (hexamethyldisilazane) is employed. A contact angle of water indicates hydrophobic of a glass substrate by HMDS vapor control using the MEMS. Keywords : MEMS, fluid control, novolac resist, HMDS, diaphragm, micro channel, contact angle, hydrophobic treatment |

||

|

||

|

||

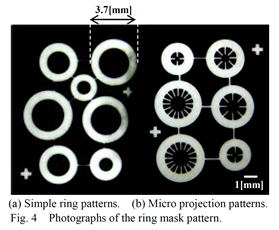

| 2011- 2. | Masayoshi Yamada, Akira Kawai “Micro Polymer Capsule Constructed with Micro Pillars Formed by Multi Laminating Method” J. Photopolymer Science and Technology, 24(6), 647-650 (2011). |

|

| [abstract] A micro polymer capsule of 6.5mm length and 4.0mm diameter is fabricated by multi laminating method. The micro polymer capsule has 56micro pillars for generating a turbulent liquid flow in the inside of capsule. As a fabrication process, the SU-8 resist film based on epoxy resin is coated on a glass substrate. A ring shape image is exposed on the resist film. After pattern development, the ring patterns are peeled from the glass substrate by dipping into HF aqueous solution. The SU-8 ring patterns are stacked in 18 layers by using the micro tweezers under the alignment accuracy of ±0.3mm. In order to adhere the SU-8 ring layers each other, an i-line resist material is pasted into SU-8 ring patterns, then baked on a hotplate at 200℃ for 10min. These functional capsule structures can contribute to develop various biological and medical MEMS (Micro Mechanical electronic system) devices. Keywords : micro polymer capsule, micro pillar, stacked structure, adhesion, MEMS, SU-8 resist |

||

|

|

|

2010年 6報

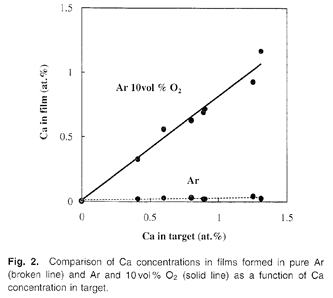

| 2010- 1. | Satoru Mori, Akira Kawai “Low-Resistivity and Adhesive Sputter-Deposited Cu-Ca Films with an Intermediate Oxide Layer” Jpn. J. Appl. Phys., 49 (2010) p075804-1~8. |

|

| [abstract] We investigated a method of producing low-resistivity and adhesive sputter-deposited copper alloy films with an intermediate oxide layer that retains its adhesion after hydrogen annealing for applications of electric interconnections for thin film circuits and liquid crystal displays. The formation of an intermediate copper oxide layer between a copper film and a substrate by sputter deposition in the presence of oxygen enhances adhesion. However, when such films are exposed to hydrogen at elevated temperatures, hydrogen penetrates the films and reduces copper oxide. This reaction generates water molecules, which aggregate at the interface between the copper film and the substrate. As a result, microvoids form at the interface, degrading the film adhesion. Sputter-deposited films with an intermediate oxide layer produced from a Cu-Ca target are adhesive even after hydrogen annealing. As films deposited in pure argon have low resistivities, it is possible to form low-resistivity and adhesive metallization. |

||

|

|

|

| 2010- 2. | Tetsuya Ono, Akira Kawai “Free fall Mechanism of Micro Liquid Droplet” J. Photopolymer Science and Technology, 23(3), 363-366 (2010). |

|

| [abstract] It is important to analyze a behavior of micro liquid droplet in order to achieve a high accuracy of LSI fabrication process such as the cleaning process, the lithography process and the etching process, patterning process and so on. By using a high-speed camera, free fall behavior of a droplet is observed. The Laplace force before falling acts to a droplet effectively. By observing the position of droplet head and tail, it is observed that the micro droplet falls faster than the free fail velocity. By employing a droplet spring vibration system, the fall nature can be clarified. Keywords : Micro droplet, Laplace, free fall, ink jet, surface tension |

||

|

|

|

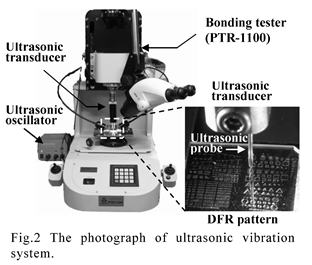

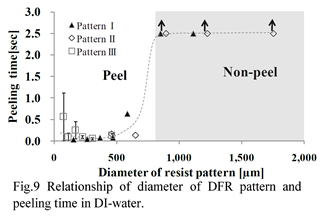

| 2010- 3. | Masayoshi Yamada, Akira Kawai “Characterization of Resist Micro Pattern Adhesion by Applying Ultrasonic Vibration” J. Photopolymer Science and Technology, 23(3), 435-438 (2010). |

|

| [abstract] An improvement of resist pattern adhesion has been recognized as one important problem that needs to be solved in micro device fabrication. Dry film resist (DFR) patterns in circle shape are fabricated on glass substrates for the adhesion test. By applying ultrasonic vibration on a edge of DFR pattern in deionized (DI) water, the time until peeling occurred is measured. The DFR pattern can be peeled from a glass substrate under the ultrasonic vibration at 25kHz. The water intrusion model into the DFR/glass interface is employed in order to discuss the adhesion behavior. Keywords : dry film resist, ultrasonic vibration, peeling strength, surface energy, water intrusion |

||

|

|

|

| 2010- 4. | Shunsuke Ohata, Akira Kawai “Dielectric Property of Solution Analyzed by using pn-junction Array” J. Photopolymer Science and Technology, 23(3), 367-370 (2010). |

|

| [abstract] Drying property of water thin film formed on a pn-junction array substrate is characterized based on dielectric analysis. In wetting processes such as pattern development, wet etching wet cleaning and drying are recognized as important processes in order to fabricate high quality electronic devices. The pn-junction array is designed with a Combination of micro pattern networks. By using a FRA (Frequency Response Analyzer) system, the drying process of water thin film can be monitored. A rapid decrease of capacitance value is observed as vanishing the micro meniscus bridge. The application of endpoint detector of drying of water thin layer is discussed. Keywords : Pn-junction, dielectric property, FRA, water thin film, micro meniscus, Laplace force |

||

|

|

|

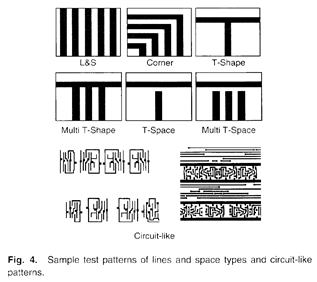

| 2010- 5. | Junji Miyazaki, Nobuhito Toyama, Akira Kawai “Double Patterning Analysis Method by Emulation using a Double-Exposure Technique” Jpn. J. Appl. Phys., 49 (2010) p035201-1~6. |

|

| [abstract] Double patterning lithography was utilized to break the resolution limit of lithography and is the most promising technology that enables shrinking of this limit. There are some barriers concerning evaluation of the double patterning process because it includes the hard mask fabrication and dry etching process. We proposed a new evaluation method for double patterning to analyze photomask performance with an easy are simple procedure using a double-exposure technique. Results showed this emulation method was useful in determining the impact of mask overlay and critical dimension (CD) error on double patterning lithography. We also evaluated the impact of mask overlay and CD. Both the overlay are CD difference were very good between the two masks. Correlations between mask and wafer cannot be detected because of the measured overlay error and the CD performance of masks was too small. |

||

|

||

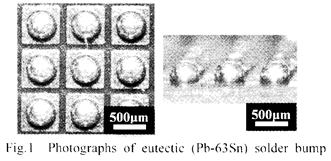

| 2010- 6. | 山田昌佳、河合 晃、大澤義征、宝泉俊寛 「超音波プローブ振動法によるはんだバンプの付着性解析」 Microjoining and Assembly Technology in Electronics (Mate), 93-98 (2010). |

|

| [abstract] The new adhesion reliability test of isolated for an isolated solder bump mounted on a glass epoxy substrate is demonstrated. The isolated solder bump can be peeled spontaneously from a glass-epoxy substrate by applying ultrasonic vibration at 25kHz on a top of solder bump. The applying time until peeling occurs is employed as a meaningful value for evaluating the adhesion reliability of solder bump. The peeling energy of solder bump can he also estimated from the vibration energy of the ultrasonic probe. The peeling energy of lead free(Sn-3.0Ag-0.5Cu) solder bump becomes high (292.4±31.1 kJ/m2) as compared with that (134.7±31.1 kJ/m2) of eutectic(Ph-63Sn)solder bump. The validity of this method is discussed. Keywords : BGA(Ball Grid Array), Ultrasonic vibration. Adhesion reliability, Interface peeling |

||

|

|

|

2009年 5報

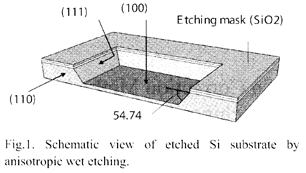

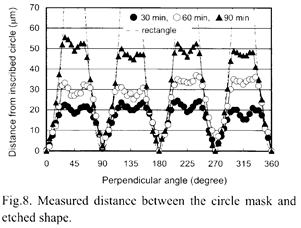

| 2009- 1. | Junji Miyazaki, Akira Kawai “Fidelity of Mask Shape and Use of a Correction Method in Anisotropic Si Wet Etching” J. Photopolymer Science and Technology, 22(6), 731-735 (2009). |

|

| [abstract] Anisotropic wet etching is widely used in MEMS fabrication processes. As this etching has different etching rates for each crystal lattice face, the etched window shape changes during etching. The fidelity of the mask shape is discussed and a correction method is proposed. It was shown that a rectangle tilted 45 degrees to (110) became octagonal and finally rectangular in shape parallel to (110), while a rectangle parallel to (110) maintained its shape. A circle mask shape also became octagonal and then rectangular. It was demonstrated that deviations from the designed shape that occur during the etching can be corrected on the mask shape in advance. This method is useful for the fabrication of circular etched window shapes. Keywords: Anisotropic etching, MEMS, Si wafer, mask, correction |

||

|

|

|

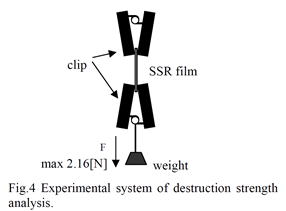

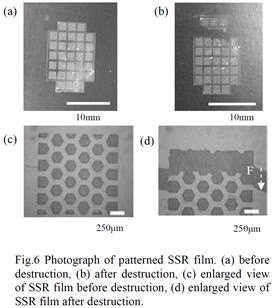

| 2009- 2. | Akihiro Takano, Akira Kawai “Analysis of self-standing structure composed by thick resist layer” J. Photopolymer Science and Technology, 22(5), 561-564 (2009). |

|

| [abstract] A self-standing resist (SSR) film in hexagonal lattice structure is fabricated and tested its destruction strength. The resist film formed on a glass substrate is removed from the glass substrate by wet etching. As a result, higher destruction strength of the SSR film with micro-hexagonal hole array can be obtained compared with that without holes. Keywords : self-standing structure, hexagonal lattice structure, photoresist,destruction strength, MEMS |

||

|

|

|

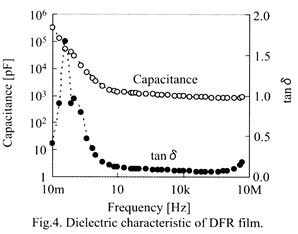

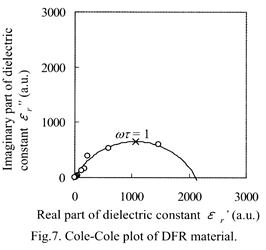

| 2009- 3. | Hiroki Sasazaki, Akira Kawai “Dielectric dispersion analysis of resist layer” J. Photopolymer Science and Technology, 22(3), 317-320 (2009). |

|

| [abstract] Dielectric properties of resist materials such as dielectric frequency dispersion,permittivity and dielectric loss tangent,which should be optimized in structural material designing, are characterized. Dielectric properties of resist materials are characterized by traditional capacitance method in the frequency range of 10mH to 5MHz. The relative dielectric constant and loss tangent from dry film resist (DFR) at 1MHz can be determined to be 3. 63 and 0.0744. The Cole-Cole plot is employed to determine a dielectric relaxation time of dipole moment in polymer structure. The relaxation time of DFR film can be determined to be 12.1s. The validity of dielectric properties of DFR film as a structural material is discussed. Keywords : dielectric constant, frequency dispersion, dielectric relaxation time, MEMS |

||

|

|

|

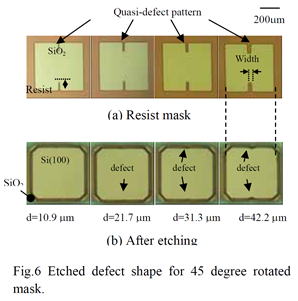

| 2009- 4. | Junji Miyazaki, Akira Kawai “Formation Mechanism of Micro Defect in Anisotropic Etching Analyzed by using Quasi-defect Pattern” J. Photopolymer Science and Technology, 22(3), 313-316 (2009). |

|

| [abstract] Anisotropic wet etching for Si substrate is a key technology for manufacturing three dimensional structures for MEMS. It is important to understand a printability of defect during this etching process to create a complete design of MEMS structure. In this paper, an impact of quasi-defects on an etched structure is investigated. It is demonstrated that a minimum defect size which is not affect on the final structure is around a half of total etching depth. Keywords : Anisotropic etching, defect, photo lithography, MEMS, Si wafer |

||

|

||

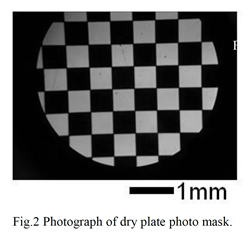

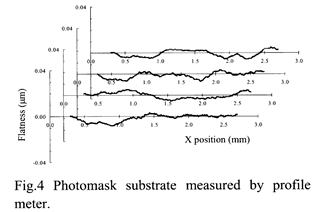

| 2009- 5. | Junji Miyazaki, Akira Kawai “Characterization of photomask substrate in optical lithography” J. Photopolymer Science and Technology, 22(5), 555-559 (2009). |

|

| [abstract] The characteristic of a photomask strongly impacts lithography performance since it is part of the optical system. In this paper, we investigate characteristics of photomask substrate flatness impact on optical lithography. It is demonstrated that high and mid spatial frequencies of substrate flatness variation are too small enough to affect lithographic performance. However, a low spatial frequency of flatness variation could cause a focal plane deviation. We show that the flatness of exposure area after tilt and curvature correction directly corresponds to an image plane deviation. Keywords : photomask, flatness, focus, lithography, AFM |

||

|

||

2008年 11報

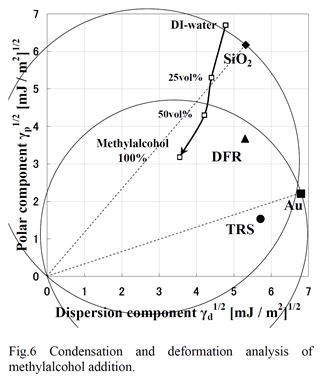

| 2008- 1. | Daisuke Tanaka, Akira Kawai “Flowing control of micro bubbles in DFR micro fluidic channel formed on metal /insulator composite substrate” J. Photopolymer Science and Technology, 21(1), 63-68 (2008). |

|

| [abstract] Dry film resist (DFR) and thick resist by spin coat (TRS) provide well-defined resist profiles with high aspect ratio, and they are also suitable for use as a permanent resist material. These resists have been widely used in the micro fluidic (inkjet, reactor, biochip) fields. The flowing control of micro bubbles is carried out in the permanent resist micro fluidic channel formed on the metal/insulator composite substrate. As the result, these micro bubbles were more likely to trap at the Au surface by controlling the surface free energy of DI-water. Furthermore, in order to prevent the bubble formation in the channel, it is effective to control the surface free energy. The O2 plasma treatment is also effective to prevent the bubble trapping. Keywords : dry film resist, thick resist by spin coat, micro channel, micro bubble, surface energy |

||

|

||

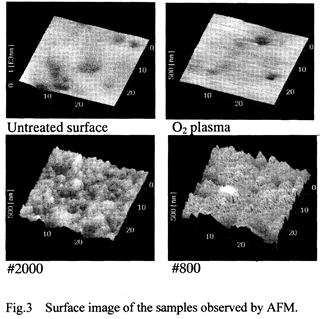

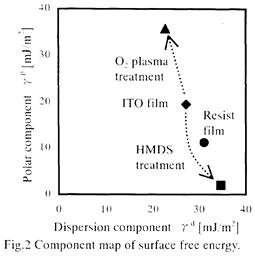

| 2008- 2. | Akira Kawai, Daisuke Tanaka, Sachito Matsubara, Masayoshi Ogata, Kazutoshi Tachibana “Wetting control of polymer solution on roughened solid surfaces by wet-blast technique” J. Photopolymer Science and Technology, 21(1), 37-42 (2008). |

|

| [abstract] Spreading of organic solution can be improved drastically on a solid surface after the wet-blast treatment. The wet-blast treatment has an ability of morphology control of various kinds of surfaces. Various organic liquid can spread spontaneously on a substrate due to spreading energy S. By analyzing surface energies of the treated surfaces, the wet-blast treatment has a similar effect of the increase of dispersion component γd , that is, hydrophobic surface. Spontaneous spreading of the polymer solutions can be explained to be negative value of the spreading coefficient. High wetting surface can be realized by an oxygen plasma treatment. However, the substrate surfaces become considerable hydrophilic property due to increase of the polar component γp , that is, hydrophilic surface. It can be considered that water vapor adsorbed the hydrophilic substrate and induce corrosion of metal components such as an electrode and micro wire lines. The roughened surface can act to prevent liquid condensation after spreading on the substrate, so-called "pinning effect". The spontaneous spreading on the substrate after wet-blast treatment can be explained on the multiplier effect of nominal dispersion increase and pinning. Keywords : wet-blast technique, surface treatment, surface roughness, surface energy, spreading coefficient, pinning effect, resist solution, epoxy solution, dispersion component, polar component, oxygen treatment, hydrophilic property. |

||

|

||

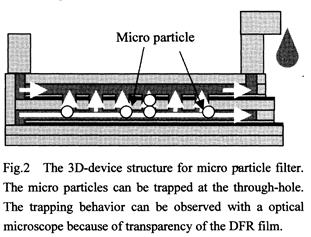

| 2008- 3. | Akira Kawai, Daisuke Tanaka, Tomotaka Ariga “Micro channel device composed by Dry film resist” J. Photopolymer Science and Technology, 21(1), 43-46 (2008). |

|

| [abstract] Micro particles path through in a concave channel and are trapped at a through hole in the filter structure. In the experiments, the deionized (DI) water is dropped on a micro 3D-filtering system constructed by a dry film resist (DFR) pattern. The filtering system is composed by an inlet hole of micro liquid drop, a micro channel, a micro filter and an outlet channel. In the result, the micro particles condensed and trapped at the different position in various shape patterns. The flowing and trapping of micro particles in a micro filtering device has been recognized as one important factor in functional micro device manufacturing. The construction of 3D-structure under acting Laplace force is accomplished without the structure destruction. The force acting on the micro particles and DFR structure is controlled by adjusting surface energy of methanol solution. We can control and predict the micro filtering system by designing micro pattern arrangement. Keywords : micro channel, liquid mixer, micro filter, 3D-structure, dry film resist, lithography, micro particle, Laplace force |

||

|

|

|

| 2008- 4. | Akira Kawai, Takashi Yamaji, Hiroshi Horiguchi “Adsorption of micro tip on various surface energy substrates” J. Photopolymer Science and Technology, 21(1), 85-88 (2008). |

|

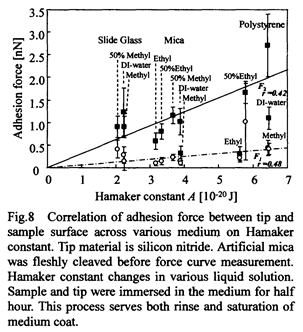

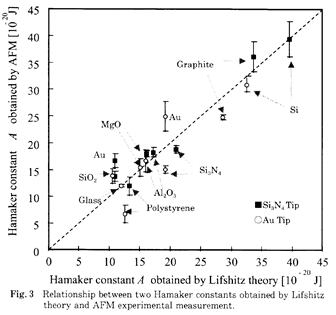

| [abstract] Interaction in liquid medium has been focused for analyzing pattern development, pattern plating, wet etching and cleaning. Adsorption forces due to surface energy of a micro tip and various inorganic substrates can be measured in liquid environment. Hamaker constant between two surfaces is determined based on Lifshitz theory. In liquid condition, Hamaker constant in this system is proportional to adhesion force between the tip and substrates. Experimental value of Hamaker constant indicates good agreement with that of theoretical one. Keywords : interaction, Hamaker constant, surface energy, atomic force microscope,adhesion |

||

|

|

|

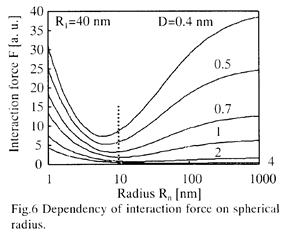

| 2008- 5. | Takashi Yamaji, Akira Kawai “Non-contact deformation of resist micro pattern due to van der Waals Interaction” J. Photopolymer Science and Technology, 21(1), 89-94 (2008). |

|

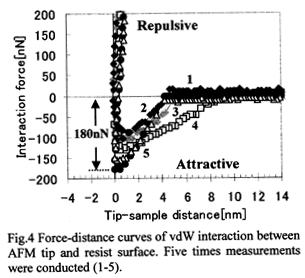

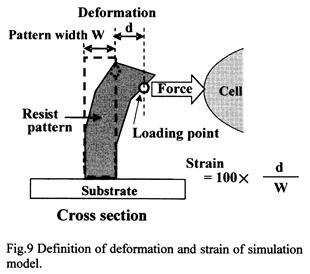

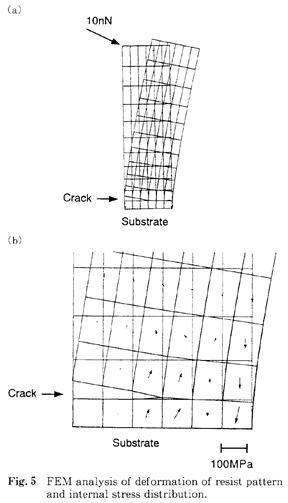

| [abstract] Deformation and stress distribution of ultra thin resist pattern are estimated by finite element method (FEM) from the measurement values of van der Waals (vdW) force and mechanical properties of resist material. In this simulation, strain and stress distribution in the simple model of the resist pattern are obtained. These results show that the thin resist pattern has high sensitivity to weak vdW force. And, the stress concentrates at an interface between the resist pattern and the substrate. The stress concentration point in the resist pattern would be destructed due to the weak force. In the experiment, the vdW attractive force is measured with an atomic force microscope (AFM) system. The maximum value of the attractive force is about 180nN. The error of the force measurement is prevented to be lower because the no torsion of the cantilever can be observed when the tip is approaching to the thin film resist surface. It is possible to discuss the realization of a soft micro chamber wall made of a soft material such as the cell. Keywords : resist pattern, non-contacting deformation, stress concentration, van der Waals force, atomic force microscope |

||

|

|

|

| 2008- 6. | Akira Kawai, Masahito Hirano and Takashi Yamaji “Nano-scale Deformation of Resist Film Surface by Humidifying and Drying Processes” J. Photopolymer Sci. Technol., 21(6), 737-738 (2008). |

|

| [abstract] Nano-scale deformation of resist film surface is analyzed by using atomic force microscope (AFM) in a humidity controlled chamber. It is clarified that the condensation size of polymer aggregates of resist material are slightly changed due to humidity change. As one major factor, Laplace force acting among polymer aggregate due to surface adsorbed water is discussed. The deformation model of condensed polymer aggregates is proposed. Keywords : resist pattern, deformation, polymer surface, water meniscus, adsorbed water, atomic force microscope |

||

|

||

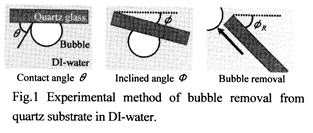

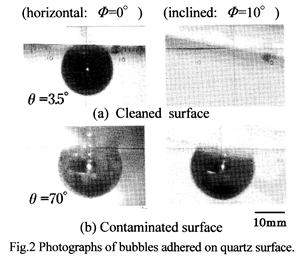

| 2008- 7. | Akira Kawai, Daisuke Tanaka “Micro Bubble Removal Depending on Glass Cleanness” J. Photopolymer Sci. Technol., 21(6), 727-728 (2008). |

|

| [abstract] One serious problem for immersion lithography is micro bubble adhesion which is responsible for various exposure failures. In immersion lithography, it seems reasonable to suppose that organic contamination of lens surface brings about micro bubble adhesion onto them. Therefore, this study is intended as an analysis of adhesion and removal of micro bubbles on quartz surfaces by the contact angle method. We discuss the adhesion and removal behavior of micro bubble on the point of the balance model of surface energy. In the consequence, the micro bubbles are more likely to adhere to the organic contaminate on the quartz substrate. Keeping cleanness of a lens surface is necessary in order to prevent the micro bubble adhesion. Keywords: immersion lithography, micro bubble, removal, adhesion, surface energy |

||

|

|

|

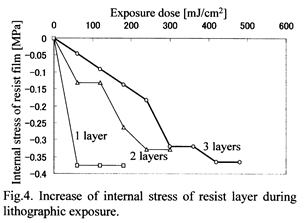

| 2008- 8. | Akira Kawai, Takashi Yamaji “Internal Stress of Dry Film Resist in Multilayer Structure” J. Photopolymer Sci. Technol., 21(6), 725-726 (2008). |

|

| [abstract] Multilayer resist process has been recognized as one candidate to realize high aspect ratio resist pattern. As one important control factor, strain and stress matching in multilayer structure should be taken into consideration. By using a strain gauge, the strain of dry film resist (DFR) in single, double and triple layer structure are measured as a function exposing time. The strain of DFR increases in proportion with the exposure dose but slightly decrease as number of multilayer. The stability of DFR multilayer structure is discussed. Keywords : multilayer structure, DFR, strain, internal stress, strain gauge |

||

|

||

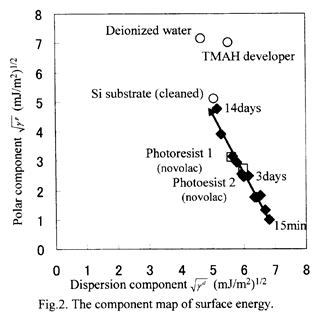

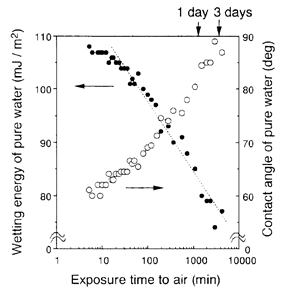

| 2008- 9. | Akira Kawai, Junko Kawakami, Hiroki Sasazaki “Surface Energy change of Si(100) Wafer by Exposing to Air” J. Photopolymer Sci. Technol., 21(6), 739-740 (2008). |

|

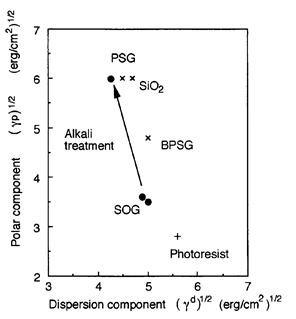

| [abstract] By contact angle method, surface energy of Si (100) wafer is measured with lapse of time in ambient condition. The polar component γsp of surface energy increases drastically but the dispersion componentγsd decreases. Surface energy γ(=γsd+γsp) gradually decreases. The surface energy change is mainly reflected with native oxide growth on the Si substrate. The polar and dispersion component of resist film corresponds mostly to those of surface energy of Si (100) after 10h exposing time to air. The spin coating condition can be designed effectively base on the surface energy model. Keywords : native oxide, surface energy, dispersion component, polar component |

||

|

||

| 2008-10. | Akira Kawai, Hotaka Endo and Daisuke Tanaka “Pinning Effect of Micro Bubbles adhered on Resist Substrate” J. Photopolymer Sci. Technol., 21(6), 753-754 (2008). |

|

| [abstract] We discuss adhesion and removal properties of micro bubbles based on thermodynamics. It is important to consider the remove technique of micro bubbles from resist surface. A micro defect on a resist surface acts to enhance the adhesion of micro bubble on to them. It is cleared that the defect such as a solid particle and a resist fragment are more likely to capture the micro bubbles due to pinning effect. It is clarified that the removal mechanism can be explained based on surface energy balance model. Consequently, one can safely state that the removal of micro bubble from the F2 excimer resist film is required a certain external load. The capture mechanism of micro bubbles at the micro defect is analyzed based on the pinning effect. Keywords : excimer resist, micro bubble, pinning effect, surface energy, adhesion, defect |

||

|

|

|

| 2008-11. | Akira Kawai, Akihiro Takano “Spreading of Liquid Drop on Resist Film Surface” J. Photopolymer Sci. Technol., 21(6), 759-760 (2008). |

|

| [abstract] Liquid drop spreading is effective phenomenon for understanding nature of wetting processes such as pattern development, etching, cleaning, immersion lithography and so on. Liquid spreading can be measured by contact angle measurement. Spreading coefficient c in Neumann model is estimated for each film surface. Results obtained in this experiment indicate that the liquid drops on resist surfaces are more likely to spread compared with those on the inorganic substrates. Keywords : resist, contact angle, Neumann spreading model, spreading coefficient |

||

|

|

|

2007年 12報

| 2007- 1. | 河合 晃、川上喜章 「原子間力顕微鏡(AFM)による微細レジストパターン内の屈折率分布の解析」 日本接着学会誌、vol.43, No.4, 140-143 (2007). |

|

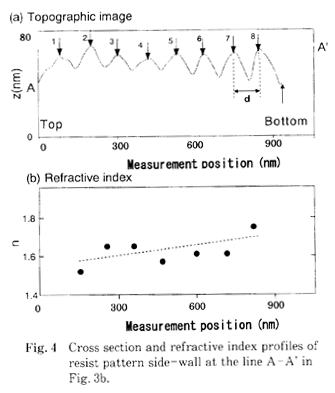

| [abstract] 光リソグラフィー技術により作製したレジストパターンの側面には, 110~180nm程度の周期の波形模様が形成される。この波形模様は,パターン露光時の定在波効果に起囚して形成される。原子問力顕微鏡(atomic force microscope: AFM)を用いて, 直径0.61μm, 高さ1.03μmの円筒形レジストパターンを基板上で剥離倒壊させて, パターン側面に形成された波形模様を観察した。波形模様の周期はパターン側面内で異なることより, レジストパターンの高さ方向の屈折率分布を求めた。その結果, 屈折率は1.51~1.79の範囲で, パターン上部から底部へ向けて徐々に高くなっていることが分かった。これは, ホットプレートを用いた熱処理により, レジストパターン底部の凝集性が高くなったことを反映していると考えられる。この手法により, 微小固体内の光学パラメータおよび凝集性を解析することが可能になる。 By optical lithography, a wave shape is formed on a side wall of a column type resist pattern due to standing wave effect which occurs during exposure process. After the pattern collapse with atomic force microscope (AFM) , surface topography of the pattern side-wall can be imaged clearly. Based on standing wave effect, refractive index distribution of the resist pattern can be estimated to be the range from 1.51 to 1.79. It is clarified that refractive index at the pattern bottom is relatively high comparing, with that of the pattern top. This tendency reflects the distribution of cohesion strength of the resist pattern resulting from the heat treatment with a hot plate. By this method, optical and cohesion properties of a micro condensed matter can be analyzed quantitatively. |

||

|

|

|

| 2007- 2. | Akira Kawai, Kenta Suzuki “Bubbles Condensed at Water/resist Interface Analyzed by Atomic Force Microscopy” J. Photopolymer Science and Technology, 20(5), 673-678 (2007). |

|